Maximum levels of oxygen in purge gas will prevent weld under bead discolorization and loss of corrosion resistance.

Inert gas purging to prevent discoloring of the weld underbead and loss of corrosion resistance is relatively common during the fabrication of stainless steels.

For the welder, however, there is very little quantitative published information available with respect to the quality of purge gas and types of purge techniques.

This article proposes maximum oxygen levels in the purge gas to ensure the absence of contamination. It also critically analyses commercially available products which have been proven to reduce the time and cost of the purging process.

Why Purge Stainless Steel Tube

High-quality joints in stainless steels between cylindrical sections such as tubes and pipes can only be made by ensuring that atmospheric gases are eliminated during the welding process.

The presence of gases, and in particular oxygen, around the molten weld can lead to wide-ranging defects. The discoloration is unsightly and in some instances might produce metallurgical imbalance.

Gross oxidation inevitably results in a reduction of mechanical properties and can cause catastrophic loss of corrosion resistance. Nitrogen contamination can result in brittleness. Gases in the weld may give rise to cracking during or after cooling.

To learn more about stainless steel welding overall, please refer to our in-depth guide on the topic. We covered MIG welding stainless steel, TIG welding, and different alloys like austenitic stainless steel, martensitic, and ferritic.

Basic Principle Of Stainless Steel Purging

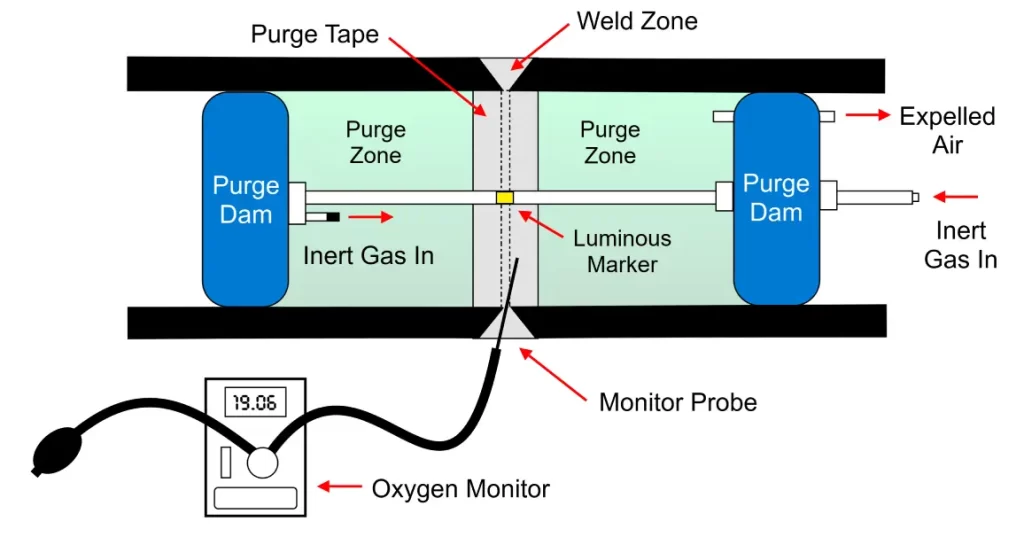

Weld root quality when making tubular joints can be ensured by applying appropriate safeguards that are based on the removal of air from the fusion zone and the provision of inert gas. This is achieved by ‘gas purging’.

Common Purging Gases

The most commonly used purging gases for stainless steel welding in the USA are commercial quality argon and helium. Purge gas flow rate and pressure need to be established, and once selected they should be included in the formal welding procedure.

Variation in purge gas quality may arise during the welding process and it may be desirable to apply continuous gas monitoring, especially to control oxygen and moisture content. For this purpose dedicated oxygen weld purging monitors are available commercially.

To learn more about different types of welding gasses and how they are used, read our guide here. We covered common welding gases and less often used mixtures to help you make the perfect shielding gas selection.

Stainless Steel Pipe Purging Procedure

The first requirement is to provide gas entry and exit points. Gas is fed through one end seal with an exit hole at the other end to prevent an undesirable build-up of pressure.

Argon shielding gas has a greater density than air and the gas inlet should be at a lower elevation than the bleed end so that air is expelled effectively from the pipe bore. The converse applies to helium which is lighter than air.

Total Purging

On small pipes and tubes, where the internal volume is small, the cost of continuous total purging may not be significant. Under these circumstances wooden or plastic discs simply taped to the tube ends will be adequate.

When total purging is impractical, perhaps because the pipe volume is large or because access is difficult, alternative containment techniques are available.

Water-soluble Products

A low-cost and effective solution to providing shielding gas coverage is to make discs from water-soluble material and seal the inside the section needing protection.

In the event that water-soluble film is not available, paper and tape can be used, although generally, this is much less suitable.

They should not be placed in position until after any pre-weld heat treatment and be far enough apart, typically 500 mm, to avoid thermal damage during welding.

The purge gas is introduced into the area between the soluble dams by means of a hypodermic tube through the weld joint line or by penetrating one of the film dams with a purging hose.

On small diameter pipes, an effective dam can be produced simply by crumpling paper and pushing it into the stainless steel pipe bore. Soluble pastes are also available and can be convenient for small diameters.

After the welding stainless steel tube is completed, the dam material can be removed by passing water into the pipe and allowing time for it to dissolve the barrier medium.

Thermally Disposable Barriers

Water-soluble products are not always acceptable and an alternative method is to use cardboard or thin wooden discs for welding stainless steel tube. These are simply cut to fit the internal diameter of the stainless steel pipe and, if necessary, taped in position to provide a gas seal. Distance between discs should be typically 500 mm to avoid thermal damage during the welding process.

The thermally disposable disc solution is convenient if welding stainless steels is to be followed by a post-weld heat treatment cycle since the card is removed effectively by incineration. Otherwise, general heating by the torch is a sound method of removal.

The water soluble and thermally disposable barriers are expedient solutions where access to the tube or pipe bore is impractical after the welding process. If access can be gained, several alternative purge gas damming techniques, which include collapsible discs, rubber gasket discs and inflatable pipe purge systems, can be considered.

These dams are normally placed in the stainless steel pipe at the time of joint assembly, a recovery cord, or a rod projecting down the access route. A spacing of 150 to 200 mm between the dams will usually prevent thermal damage during welding but it should be noted that greater spacing is prudent if pre-weld heat treatment is to be applied.

However, there are products now available that have excellent high-temperature thermally resistant properties that are eminently suitable for use with pre-heated pipework.

Collapsible Disc Barriers

Discs can be made from any readily available rigid sheet material; plywood is a good medium if in-house manufacture is planned. The discs are split across the diameter and hinged and a sealing pad of synthetic foam bonded to the periphery.

Cords attached to the discs are used to collapse the dam after welding and to remove the discs from the pipe.

Rubber Gasket Dams

A rubber disc can be sandwiched between a pair of wooden or metal discs and some adjustment to diameter can be affected by applying axial pressure.

This gasket technique is not collapsible and after welding steel tube and pipe, the discs must be pulled out past the weld root, an operation that may cause difficulties.

Inert Gas Inflatable Systems

By far the most efficient purge gas containment method is to use specially designed inflatable pipe purging systems.

The systems are manufactured from rubber with a protective nylon cover.

One is placed on each side of the joint and best inflated using the purge gas itself.

Such systems are much preferred since they obviate any difficulties that might arise by water contamination of the weld zone from less suitable materials and from air entering the weld zone from air inflatable systems.

How To Purge The Stainless Steel Tube and Pipe

After you complete standard weld preparation, prepare your gas tungsten arc welding equipment, and assemble any of the dam systems disused above, it’s time to purge the stainless steel pipe and begin the welding process.

The Pre-Purge Process

A pre-purge is used to displace air present in the pipework system or dam volume. Numerous factors control the pre-purge time such as stainless steel tube diameter, purge volume, and maximum permitted oxygen level.

A common misconception is that increasing the purge flow rate will reduce the purge time. This is fallacious. An increase in flow rate increases turbulence and results in unwanted mixing of purge gas and air and can actually extend the purge time.

As a general rule, the pre-purge flow rate and time should allow for about five volume changes in the pipe system or dam volume but a typical gas flow rate will be in the region of 20 l/min.

Weld joints that require a root gap or which exhibit bad end matching, both of which characteristics provide an unwanted leak path for the purge gas, can be sealed by tape.

Oxygen and moisture levels in the purge gas should be checked using appropriate equipment with checking taking place at the outlet point. Where dam inserts are being used the outlet point needs to be extended with a flexible pipe to a convenient access position. If this is impractical a system that has the purge inlet and outlet in the same dam unit should be used.

Although 0.01% residual oxygen is a suitable working level for materials such as stainless steels, the level needs to be as low as 0.001% when welding the more sensitive alloys based on titanium and other reactive metals.

The Weld Purge Process

Once the quality of the gas in the dammed volume has reached the required level, gas flow can be reduced to about 5 l/min for the welding operation.

On a more practical level, it should just be possible to feel the gas flow from the exit point. Excessive flow can cause the internal pressure in the pipe to rise and create a concavity in the weld root geometry and in more extreme cases can cause complete ejection of the molten weld pool.

On joints that are not fully sealed to restrict leakage, a higher flow rate will be necessary to avoid contamination. Towards the end of the weld run, however, as the joint becomes permanently sealed, the gas flow rate will need to be reduced to avoid over-pressurization.

Purging Stainless Steel Costs

Providing precise data on cost comparisons between the different purging techniques is difficult not least because the pipe diameter and wall thickness have a profound influence on the cost. Furthermore, it is impractical to use removable inserts in sealed pipes or in pipes and tubes with diameters much below 100 mm.

It is impractical therefore to be specific across the entire spectrum of diameters and welding procedures, other than to say that savings can be significant when commercial purging systems are employed.

As an example, users report that a 900 mm diameter pipe can be fully purged to less than 0.1% oxygen in under 10 minutes when using the ‘Argweld™ commercial systems illustrated. There are reported savings in excess of 80% on purge time compared with alternative purging systems so that inert gas usage can be reduced dramatically as a result. (‘Argweld’ is a registered trade name of Huntingdon Fusion Techniques Ltd.)

It is clear from this basic analysis that where several welds have to be made on similar pipe diameters there can be genuine cost savings when using inflatable weld purge systems as the sealing medium. Add this to the technical advantages of reliable sealing and ease of use and the inflatable purge concept can be seen to offer significant attractions.