TIG welding is one of the most challenging processes to master, but it is often required when weld quality, aesthetics, and reliability are required. GTAW is the most suitable method for delicate and exotic metals, but to get there, you will need a lot of practice.

If you are a beginner, the first thing you should get the hang of is the TIG arc starting techniques.

You noticed TIG welders have lift arc, high frequency, or scratch start method, so if you are wondering what they mean, you are in the right place.

- How does a TIG Arc Start?

TIG arc can start using one of three standard techniques: scratch start, lift arc, or high-frequency current (HF). A high frequency is almost always the best start.

- How Do You Start An Arc Lift TIG?

You start a Lift start method by touching the workpiece with a tungsten electrode, starting current and shielding gas, and then quickly lifting the TIG torch. The unit senses once you lift the torch and start the arc with a low risk of contamination.

- What Is TIG Scratch Start?

TIG scratch start is the oldest arc starting method, where you have to scratch the workpiece with a tungsten electrode to start the arc. Then, you have to lift the torch quickly, so the tungsten doesn’t stick but not too high to extinguish the arc.

- What is better, Scratch Start or Lift Arc?

Lift arc is significantly better and cleaner than the scratch start, as there are no tungsten particles in the weld pool, and it is easier to use and master.

- High-frequency vs Lift TIG welding, which is better?

High-frequency is the best arc start as it is easy to perform, and the tungsten doesn’t touch the workpiece, so it is a clean start technique. However, lift TIG is only more suitable when there are devices sensitive to frequency, such as CNC, cell phones, computers, towers, or airports.

How Does A TIG Arc Start? – GTAW Arc Starting Techniques

In GTAW (TIG) welding, a welding arc is formed between the tungsten electrode and base metal. The non-consumable tungsten electrode carries a welding current without melting, as the properties of the metal allow it to withstand a temperature of 11,000 F (6,000 C).

To start the TIG arc, you can use three different techniques:

- Lift arc.

- Scratch start.

- High-frequency start.

Each arc starting method is performed differently, and it has its ups and downs and will work in different welding operations. Therefore, you will need to understand the basics to choose the best one.

So stay tuned to learn how the proper arc start method can impact the overall weld quality, ease of use, and convenience during TIG welding.

TIG Scratch Start Method

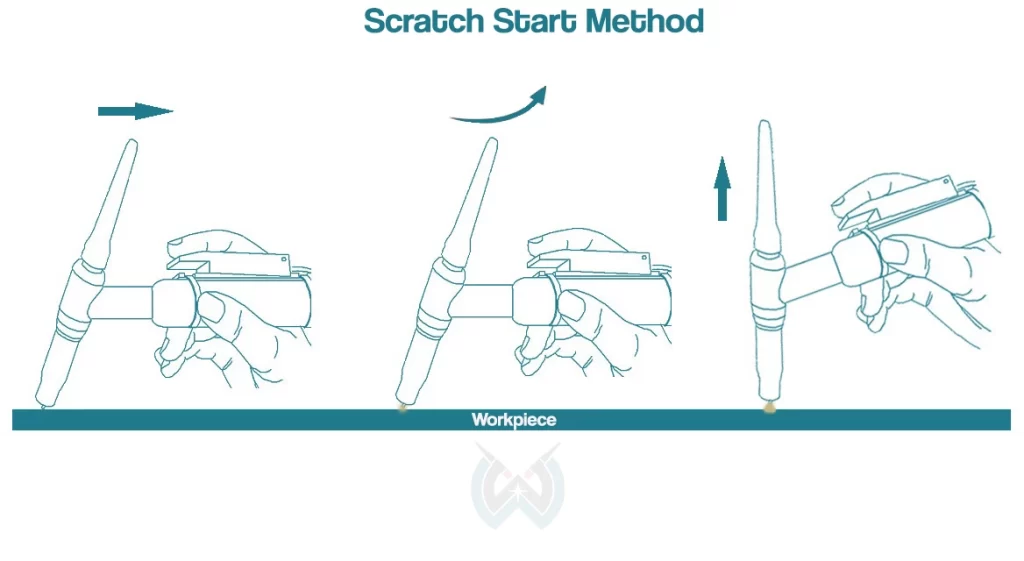

TIG scratch start is one of the oldest TIG arc starting methods, and today, it is usually seen in budget TIG welding machines that are mainly aimed at Stick welding. Fundamentally, scratch start in TIG reminds me of lighting a match. You will have to start shielding gas and current and flick the base metal with a TIG tungsten electrode until the arc appears.

As soon as the arc starts, you will have to lift the TIG torch so tungsten doesn’t stick to the base metal, but meanwhile, you can’t lift it too high, as the arc can extinguish. Therefore, you can understand this isn’t really a beginner-friendly arc initiation method, and there are more issues with it.

While you scratch the workpiece, you can damage the tungsten electrode, causing welding defects and tungsten inclusion. Therefore, you will need to sharpen your electrode more often and be cautious when TIG welding delicate metals.

Fundamentally, scratch start TIG seems like a Stick arc welding start, where you sometimes get a decent result, but sometimes tungsten sticks to the workpiece. That’s why this method was eventually replaced by other arc starting methods. However, as I sad above, you can still find it in some cheap TIG welders, but I don’t recommend it unless you are on a super tight budget.

Lift TIG Arc Starting Technique

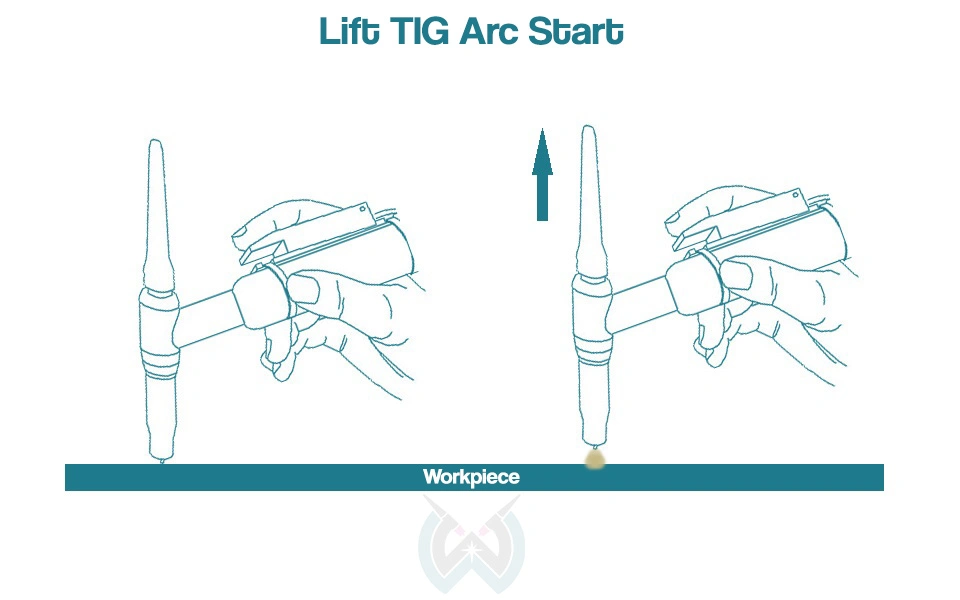

To start a Lift arc with your TIG welder, you will have to touch the base metal with your tungsten electrode, start a current and shielding gas with your foot pedal, and then quickly lift it. The machine senses the gap, and the arc initiates really fast. With low voltage output, there is no risk of tungsten sticking, and you will hear a little pop sound.

The lift arc technique seems similar to scratch start, and many confuse these two. However, there is one significant difference.

As a result of minimal contact between tungsten and the workpiece, the lift arc TIG clean process. Even though there is still that one slight moment where you have to touch the metal, a lift start is much cleaner than a scratch start but not as clean as a high-frequency arc start.

While the lift arc method is significantly better than scratch star in the TIG welding process, there is still a risk of contamination. If you tune up starting amperage too high, the tungsten point can stick to the workpiece, causing molten tungsten to cause tungsten inclusions and other defects.

TIG High-Frequency Arc Start

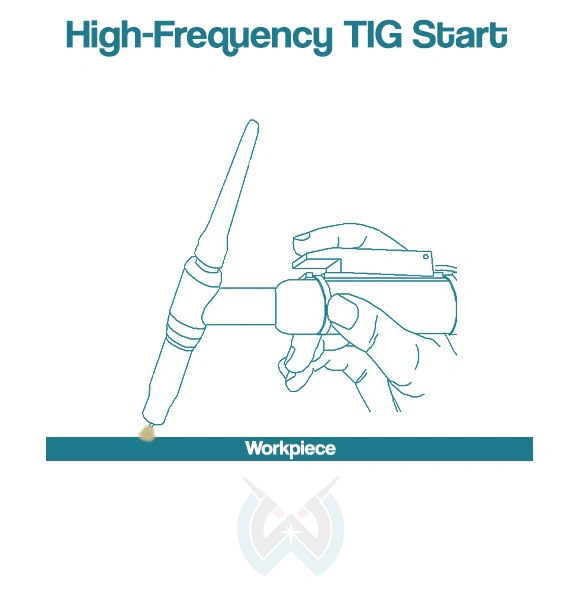

The high-frequency start is one of the most advanced in the TIG process, as it will ensure maximum cleanliness in your welding procedures. To get the HF ignition, you will have to put your tungsten electrode close to the workpiece, hit your foot control, and the arc will initiate automatically, with a bit of poof sound.

You don’t need to touch the workpiece with your tungsten, meaning there is no, to little contamination. As a result, the high-frequency start is the only suitable option for TIG welding aluminum. HF ignition machines can be pricier compared to the other two start methods, but they will produce the highest quality welds.

Yes, a high-frequency start is the cleanest possible so far, but there is still some risk of contamination. However, the contamination is the result of human error, as you can damage the weld pool by over-sharpening the tungsten or over-tuning the amperage.

Nonetheless, HF start is a user-friendly method you can use to get positive arc starts every time, with decent results and the best welding consumables utilization. The components that induced an HF start were significantly pricier in the past, but today, you can find decent-budget HF TIG welders.

Lift Start Vs Scratch Start TIG Welding

If you ask me or any other seasoned welder out there, I would choose the lift arc TIG start over the scratch start technique every single time. Ease of use, cleanliness, and overall results are where Lift TIG takes an edge. Yes, they might seem similar to some, but I occasionally struggled to ignite the arc with a scratch start, even after years of experience doing it.

The only reason to ever choose scratch start TIG over the lift TIG is the budget. Scratch start TIG welding machines are super cheap, sometimes just over $100, but they have become scarce in today’s market. Due to way too many cons, manufacturers luckily succeeded in making cheap machines with at least lift TIG.

HF Start Vs Lift Arc TIG Welder

The high-frequency is the best, or the best-known, TIG welding arc start method so far. The introduction of HF ignition brought many advantages to TIG welding. The welders could easily weld materials such as aluminum, stainless steel, or non-ferrous metals prone to weld defects and contamination. The weld’s quality is unmatched, which is why it is commonly used in process piping or welding pressure vessel. Even though Lift TIG will work just fine in your everyday garage work and DIY projects, I would always choose the HF over the Lift arc TIG machine.

The only reason to go for the lift TIG over the HF ignition is when welding near frequency-sensitive devices such as CNC tables, radio towers, telephones, or airports. In addition, HF machines today are affordable, so you won’t have to break the bank to get excellent results, clean welds, and ease of use.

After everything we said, I don’t think we should even compare HF start vs scratch start TIG, as the HF is unmatched.

Final Thoughts

While there are three different TIG arc starting techniques, scratch, lift, and HF, your ideal choice is an HF ignition. With HF, you don’t have to touch the base metal, so there is no risk of tungsten contamination. The arc starts super easily, and you get excellent results as long as you get your power source control and weld preparation right.

The alternative is the Lift arc, where you touch the piece and lift the torch. You can work with a lift arc around the garage or home projects, but you cannot use it to weld delicate metals such as aluminum. Nonetheless, it is a better choice than scratch start and HF when welding near frequency-sensitive devices.

The scratch start is an outdated technique you can struggle a lot to work with. It will require a lot of time and patience, and you can still fail, even after hours of practice. That’s why scratch start TIG is not so common today.

Resources:

- https://americantorchtip.com/blog/tig-welding-scratch-start-lift-start-or-high-frequency/

- https://www.everlastgenerators.com/blog/hf-start-vs-dc-lift-start-tig-vs-scratch-start

- https://www.tws.edu/blog/welding/how-to-strike-an-arc-in-tig-welding/

- https://www.weldclass.com.au/blog/40-tig-welding-what-is-scratch-start-lift-arc-and-hf-ignition-

- https://industrialmachinerydigest.com/industrial-news/features/understanding-tig-arc-starting-techniques/