“A good handyman is nothing without his tools”…

The same thing goes for welders as no matter how skilled you are, you simply need the help of your tools to get the job done. However, skills are equally important.

The same thing goes for welders as no matter how skilled you are, you simply need the help of your tools to get the job done. However, skills are equally important. To get the best possible results a combination of a welder’s expertise and useful equipment is needed.

Let’s get more familiar with the type of welding tools and accessories every beginner welder should be using.

Although all of them might seem important, there are some welding tools that are ranked above others in terms of necessity. Your welding machine is of course a must, but there are more tools that you need to add to your arsenal, some essential and some useful. Certain safety gear, power tools, marking tools, all of them are equally important and should be added to your welding tools list. Let’s go over some of the must-have welding tools.

Safety Gear And Accessories Welder should own (From Helmet to Knee Pads)

Safety is your number one concern when starting any welding project. You can’t achieve the best welding results if you don’t protect yourself first and foremost. The right protective clothing, safety equipment, and supplies (of which welding helmet should be first) will have to be all on your shopping list. That way, you can protect yourself and secure the area around you.

1. Welding Helmet

A welding helmet is the most important part of your safety set as it protects one of the most sensitive parts of your body – the eyes. A helmet can cover and protect your eyes from flashes and prevent welder’s blindness. The welding helmet can also protect your face and neck from burns and sparks. Every welder should have a durable welding helmet made out of quality materials as those also prevent light and radiation from coming through.

2. Welding Jacket

A welding jacket is designed to protect your entire upper body from high temperature, UV rays and weld spatter during work. But make sure you have a durable, fire-resistant jacket with long sleeves and a buttoned-up collar. Besides protecting your body and arms from the outside, you have to be careful that hot metal pieces don’t get inside. The most durable materials include leather, wool, and denim. (but leather is the best)

3. Welding Gloves

You need a pair of good welding leather gloves to protect your hands from burns. A pair made out of resistant lining is what you should be looking for. Also, gauntlet-style gloves are the best ones to use as they can protect your wrists besides your hands. Different types of welding gloves are used for various welding projects and usually include TIG welding gloves, MIG welding gloves, and Stick welding gloves.

4. Safety Glasses

Safety glasses can be used as a substitute for welding helmets, but should not be considered as such. They are not a complete face shield and only protect your eyes. For that reason, they should only be used during certain types of welding processes that don’t result in too many sparks and weld spatter. A good pair of safety glasses is designed to shield your eyes from heat, optical radiation, flying debris, and liquid chemical splashes.

5. Welding Boots

Heavy-duty shoes can protect you from heavy objects that may land on your feet. This is why you should get high-quality boots that are comfortable and at the same time and have steel protection for your toes. More importantly, they should come with electrically non-conductive soles

6. Welding Respirator

A variety of gasses and fumes are created due to the nature of the welding process that one uses. Protection comes in the form of a welding respirator. Every welder should wear one if they are working in a tight area where fumes are in danger of building up.

7. Welding Knee Pads

Wearing welding knee pads will allow you to work effectively while crouching or kneeling. A lot of pieces of metal end up on the ground, depending on the welding process used. Knee pads will protect your knees from all the shrapnel, debris, and jagged pieces that end up on the ground. The good thing is to have your own if you plan to be a professional welder at some oil and gas pipelines or build large oil tanks. Eight hours on your knees is, trust me, not good for your legs.

8. Fire Extinguisher

Wearing welding knee pads will allow you to work effectively while crouching or kneeling. A lot of pieces of metal end up on the ground, depending on the welding process used. Knee pads will protect your knees from all the shrapnel, debris, and jagged pieces that end up on the ground. The good thing is to have your own if you plan to be a professional welder at some oil and gas pipelines or build large oil tanks. Eight hours on your knees is, trust me, not good for your legs.

Hand Tools

After securing your work area, you should equip yourself with the necessary power tools needed for work. A good welding machine is a starting point, but there are other pieces of welding equipment that you should add.

Grinder Angle

“Grinder and paint will make you the welder you ain’t” But seriously an angle grinder may be a basic tool found in a workshop but is one of the most important ones. Angle grinders are used to polish a piece of metal or remove any excess materials from it. That way, the sheet metal you are working on is cleaned and ready for welding or cutting.

Hacksaw

You may not be able to use electricity nor have access to a power outlet. A hacksaw is a part of hand tools that are used for manual metal cutting.

Cutting metal with it may be harder but it is easy to use and even works better in certain situations.

Slag & Chipping Hammer

Welding slag builds up and needs to be cleaned for proper work to be done. It may be a cause of frustration for some welders but the area needs to be cleaned before doing any work. Slag can be chipped away with a chipping hammer and every welder should have a certain type of hammer close at hand.

You could also make a hammer yourself. Like awesome chain made chipping hammer above.

Steel Wire Brush

After removing all the layers of slag, you need to brush the area a bit. A weld can be cleaned up with a wire or metal brush so it becomes smoother.

Hand File

A hand file or a metal file is another handy tool to have. It is used to ground edges and removing metal burrs. These tools are necessary for flattening a welding profile or simply for quickly remove welding metal.

Welding Tools and Accessories Marking And Measuring Tools

For your work to be perfect, you need a set of measuring and marking tools to prepare everything before you start. These include various soapstones, permanent markers, and even scribes.

Soapstone Markers

Using soapstone for marking may seem like an ancient technique, but it is highly efficient. It has been around for decades and its qualities are that it is highly heat-resistant, meaning that your markings won’t melt when you apply high heat.

Permanent Markers

A permanent ink marker is a perfect and quick substitute for soapstone. Black ink dries fast and can be applied to wet and oily pieces of metal equally well.

This is excellent for marking your sheet metal when plasma cutting or for when you need to use an angle grinder.

Scribe

A scribe is a sharp hand tool that allows you to leave markings on a surface of a workpiece.

A good scribe that has a durable tip will allow you to mark your metal with ease. It is very good if you get a scribe that has a Tungsten tip. They will last long and will make it much easier to leave markings on the metal.

It is very convenient when you need to mark the metal for cutting or for any other needs.

Automatic Center Punches

An automatic center puncher is basically an advanced scribe. They are spring-activated and you can use them with one hand.

You can leave indentures on the surfaces you are working on and trace them later on.

This is very useful if you will be drilling holes on the sheet metal. In order to drill accurately placed holes you need to mark them across your metal. Sure, drilling one hole is not a problem but what happens when you need to drill 20 of them and all of them need to be placed accurately?

Square Tools

In order to measure exact 45 or 90-degree angles, a square tool definitely comes in handy. This tool is useful when you need to be really accurate.

Using any half measures will not suffice. Working without a square tool around will make your work become a horrible experience.

Need something at a 90-degree angle? Oh let me just get that flat sheet metal I have laying around that has a square shape and see if I can align it with my work to get a proper angle. Yeah, no. You are way better if you have a very cheap-to-buy tool that has been used for decades for this line of work. Don’t skip on this one.

Once you start using it, it will just become an intuitive manual action for you and you will not even notice that you have this tool but it will be making sure that your angles are accurate.

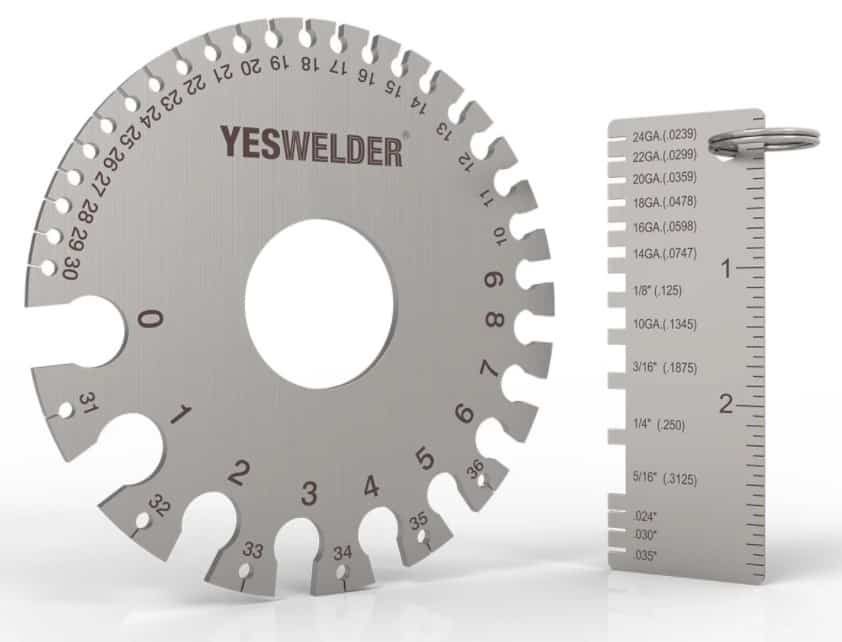

Sheet Metal Gauge

Knowing the thickness of your work piece is important. That way you will know which type of welding tool you can use on it. Therefore, a sheet metal gauge is needed to determine its thickness.

This is especially important for beginners as you probably can’t eyeball the thickness of the metal.

On another hand, if you are a seasoned welder, then you may need it too because despite your expertise sometimes there are unorthodox cases where it is helpful to have a tool that can estimate the closest thickness to any of the standard thicknesses the sheet metal is made in.

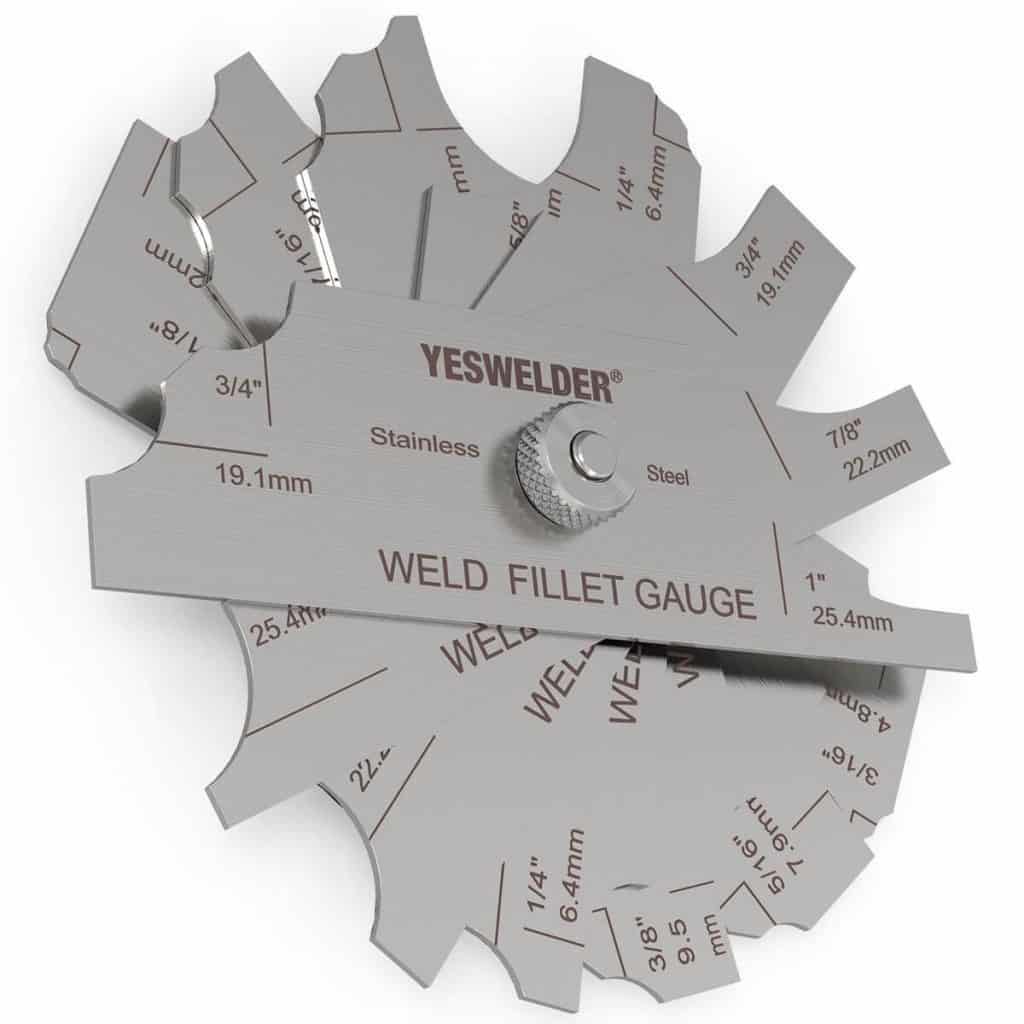

Welding Gauges

A welding fillet gauge is used to determine the fillet weld and also measure the leg length and throat thickness. It is a useful and important tool to have and can save you a lot of trouble later on.

This is especially important for beginners. You will be checking your welds quite often with it.

Overall this is a small tool that fits in your pocket but it fulfills a very important aspect of welding work. Making sure that the weld dimensions and proportions are accurate and the way they suppose to be.

Welding Support Tools

For the best work results, a welder needs a steady and robust surface to work on. There a welder can place the tools and pieces of metal and start welding with ease.

Welding Table

A good welding table is there to improve your work and provide convenience for faster results. A high-quality bench can come with an adjustable height, guide rails, corner clamps, and tool storage.

This is nonnegotiable. You need a high-quality table if you will have a welding shop or a serious welding setup in your garage. If you are not going to work on very serious work, however, then any welding table will do but you will need it.

You could buy a welding table but you could also build it yourself.

Welding Cart

Welding carts may not be as essential as other tools in your workshop, but they do come in handy. This is particularly noticeable when needing to move heavy machines around.

More importantly, they are a time saver. It is not just difficult to move heavy welding equipment but it is time-consuming. It can also be dangerous if you are working in a small space and trying to physically move heavy and bulky things around.

Welding Magnets

Applying welding magnets allows you to hold certain pieces of metal together that you are currently working on. That way both your hands are free and it improves safety as well as making things more convenient.

These are incredibly helpful to have and especially when working on more complex projects. Holding 3 or 4 pieces of metal in place could easily prove impossible without some sort of tool. Welding magnets are one of the tools that can be used to help you with that.

Welding Clamps

Welding clamps, c-clamps, and pipe clamps are needed to hold two pieces of metal really tightly that you are working on. They are particularly useful when welding sheet metal and are far better than magnets.

Other Useful Welding Tools and Consumables

To get rid of your mistakes and improve your work, there are a whole lot of additional tools that one should have.

Tip Cleaner

Oxy-Acetylene tips need to be cleaned after you are done using them. A tip cleaner can do the job for you. They come with various welding files, as well as a flat-file, to help you clean the welding tips properly.

Welding Pliers

Welding pliers can be useful in all sorts of situations. They really come in handy when cleaning the splatter out of a nozzle to improve gas flow. Other things where pliers are useful is when trimming the wire or helping you remove the nozzle itself.

Vice Grips & Pliers

It is not safe to touch hot pieces of metal even if you have some welding gloves on. Therefore, vice grips and certain welding pliers should be used instead. Additionally, besides simply handling pieces of metal, vice grips can also act as a substitute to clamps and hold pieces you are working on together.

Flint Striker

A flint striker is used to safely light a gaseous fuel aflame. It is a very useful tool to have and can be crucial for any project.

Just make sure you get something that can work in all conditions. Indoors and outdoors.

MIG Nozzle Gel

If you are using a MIG welder you can use MIG protective gel to secure your MIG gun.

Spatter can interfere with the gas flow so applying some gel to the nozzle of your gun can prevent the spatter from sticking out.

This is especially helpful when doing flux core welding due to more spatter that is generated. Simply applying some gel will be of great help. You will probably still need to remove your nozzle from time to time to clean it up but to clean up the gel, not the spatter.

Welding Wire

Choosing an appropriate welding wire for a certain project is important.

There are various wires that are supposed to be used depending on the material and the welding process.

Welding wires are melted due to high heat and form filler material on a weld when joining two pieces of metal together.

Frequently Asked Questions [F.A.Q]

What Are The Welding Accessories?

There are many types of welding accessories and you can read about most of them in the article above.

Why Is Welding Safety Gear Important?

Welding is a dangerous process that can if used improperly, cause harm to a welder. Safety gear is important in protecting the worker from any kind of harmful situation that might occur.

Do You Need Welding Accessories?

Yes, you do. Welding accessories can improve safety, allow you to finish your work in an easy way, and improve your overall work.