In the past, gas welding was one of the most common welding processes due to economics and ease of use. Even though there are more popular welding techniques today, people still choose gas welding in specific applications.

However, to achieve satisfying gas welding results, you must provide a proper gas welding flame.

This article will discuss and explain the types of welding flames, when they are used, and how gas welding flames can affect the weld.

What are Gas welding Flames?

While different welding techniques use heat to join metal, the heat sources differ. For example, different types of gas welding flames heat the base metal to form a joint in gas welding.

The flame generated during the gas welding process results from a reaction of fuel gas and oxygen. The fuel gases used can be acetylene, propane, butane, hydrogen, or natural gas.

Each one of these combinations provides a different temperature, but the most commonly used is oxyacetylene welding. Oxyacetylene welding was first developed in 1903 by two French engineers, Edmond Fouché and Charles Picard.

Properties Of Oxy-acetylene Flame

Oxyacetylene welding commonly referred to as gas welding, is a process that relies on the combustion of oxygen and acetylene.

During the early 20th century, before the development of Arc welding, oxyacetylene gas welding was the only method for welding steel. It was an effective and economical process for welding during that period.

Depending on the ratio of oxygen to acetylene, the flame can reach a temperature of about 6300 degrees Fahrenheit. This combination produces the highest temperature during complete combustion compared to other fuel gases such as propane, butane or hydrogen, and carbon monoxide.

Types Of Gas Welding Flame

Depending on the ratio of acetylene and oxygen, there are three main types of gas welding flame: neutral flame, oxidizing flame, and carburizing flame. Each carries a name off the chemical effect it provides during heating.

- A neutral flame, also referred to as a balanced flame, forms once the acetylene and oxygen ratios are even. As a result, this gas welding flame has no chemical effect on the metal being welded.

- A carburizing flame is formed due to excess acetylene but compared to a neutral flame, it causes chemical changes, making it unsuitable for welding steel. That’s why this type of flame is used in welding metals that don’t absorb carbon.

- An oxidizing flame is formed due to excess oxygen, and as a result, it produces higher heat. However, oxidizing flame causes oxidation, making it suitable for metals such as copper and zinc.

These flames not only differ in chemical nature but also differ in appearance. All three flames consist of 3 zones which can help you distinguish them:

- The inner luminous zone is where hot oxygen and acetylene mix physically.

- The intermediate zone, between the inner and outer areas,

- The outer zone is where the secondary combustion of the mixture takes place.

| Properties | Neutral Flame | Reducing Flame | Oxidizing Flame |

|---|---|---|---|

| Inner Core Temp (ºF) | 5850 | 5252 | 6330 |

| Intermediate Temp (ºF) | 3800 | 4530 | 3810 |

| Outer Core Temp (ºF) | 2300 | 2320 | 2320 |

| Noise | Hissing sound | Noiseless | Extreme Noise |

| Flame Size | Medium | High | Low |

Neutral Flame Characteristics

The neutral flame is the starting point for other flames, as it has a one-to-one ratio of oxygen and acetylene. In addition, the neutral flame has a clear, well-defined, or luminous cone indicating that combustion is complete.

This flame got a name since it doesn’t cause any chemical effects on the base metal. Therefore, a neutral flame is often a go-to flame for welding most ferrous metals such as mild steel, stainless steel and cast iron, but it can also be used in welding copper and aluminum alloys.

These neutral flames are obtained by starting with another acetylene flame with the inner cone’s “wing” expansion. The plume will disappear when the acetylene flux decreases or the oxygen flow increases. This is achieved by gradually opening the oxygen valve to shorten the acetylene flame until a clearly defined internal cone appears.

Neutral welding flame adjustment is used for most welding operations and preheating during cutting operations. In the neutral flame, the temperature at the inner cone tip is approximately 5850ºF (3232ºC), while at the end of the outer cone or envelope, the temperature drops to approximately 2300ºF (1260ºC).

Neutral or balanced flame produces a molten metal puddle that is quiet and clear when welding steel. The metal flows easily without boiling, foaming, or sparking. Using equal proportions of acetylene and oxygen creates a cover that prevents oxidation. This also produces carbon dioxide, which shields the metal surfaces.

Carburizing Flame Characteristics

To create a carburizing flame, you will have to start with a neutral flame.

Then, slowly open the acetylene valve to increase the ratio of acetylene to oxygen. As the ratio increases, a white stream extends from the inner cone.

This white feather is called the acetylene feather. If the acetylene feather is twice as long as the inner cone, it is known as a 2X flame, which expresses the amount of excess acetylene.

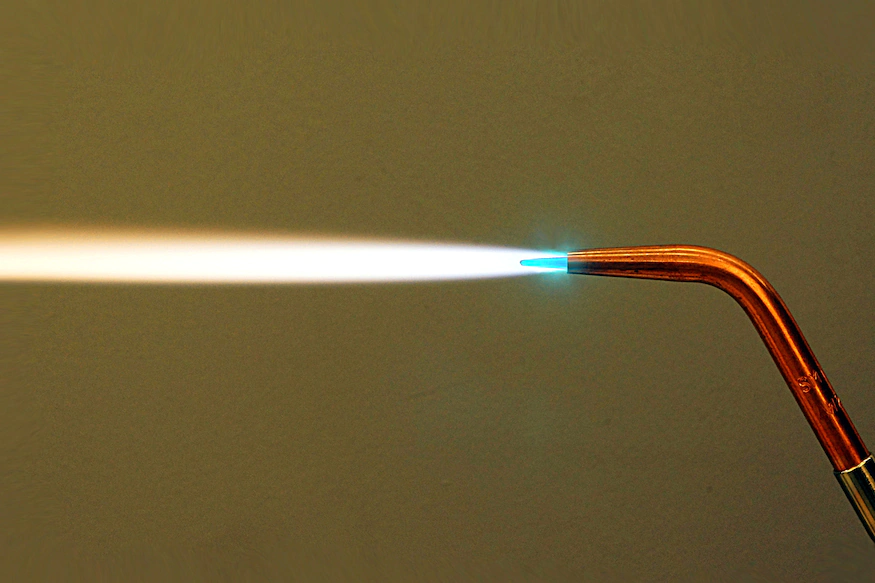

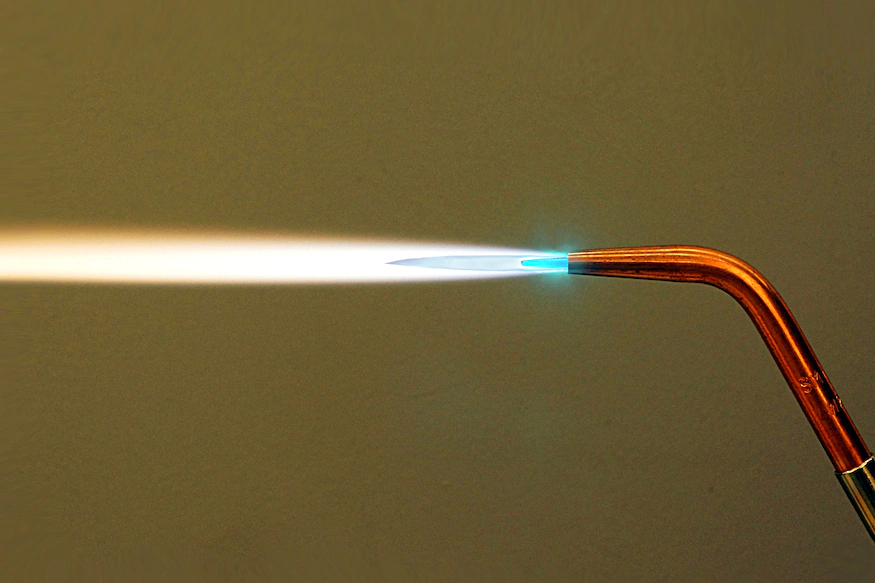

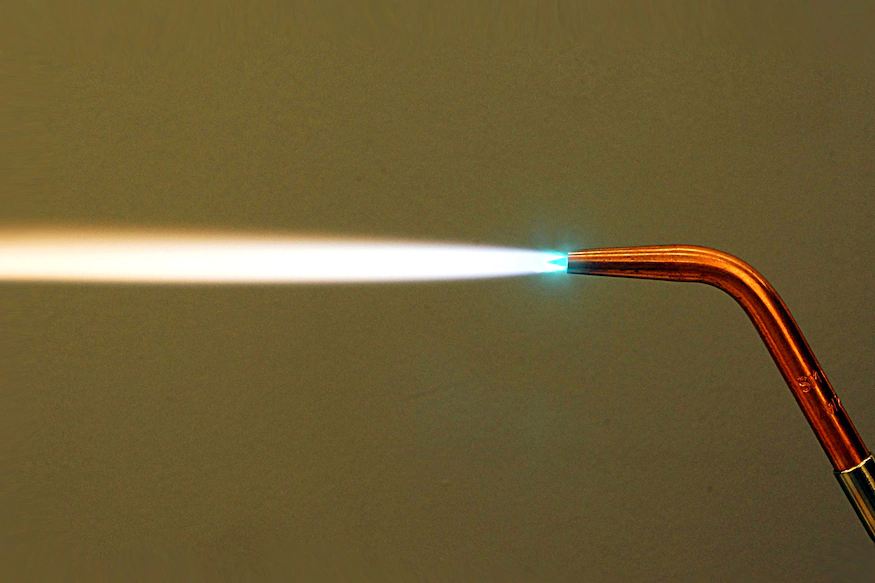

The reducing or carburizing flame can consistently be recognized by the presence of three distinct flame zones. There is a clearly defined bluish-white inner cone, a white intermediate cone indicating the amount of excess acetylene, and a light blue outer flare envelope.

This type of flare burns with a coarse rushing sound. It has a temperature of approximately 5700ºF (3149ºC) at the inner cone tips.

This flame chemically reacts with metal and forms metal carbide. Due to this reason, this flame is not suitable for metal that absorbs carbon such as nonferrous metals.

The carbonating flame is beneficial for welding high carbon steel and withstands such non-efficient alloys as nickel and monel.

Oxidizing Flame Characteristics

Oxidized welding flame is produced when more oxygen is added to acetylene. Oxidizing flame is hotter than natural flame and has clearly defined two zones.

The inner zone has a very bright white color and has a temperature of about 6300ºF (3482ºC), while the outer flame is blue.

An oxidizing flame can also be recognized by its distinct hissing sound.

When applied to steel, an oxidizing flame causes the molten metal to foam and give off sparks. This indicates that the excess oxygen combines with the steel and burns it.

That’s why this type of flame is widely used in welding zinc, copper, manganese steel, and welding cast iron. A slightly oxidizing flame is used in steel and cast iron torch brazing. A stronger oxidizing flame is used in the welding of brass or bronze.

Pros And Cons Of Oxyacetylene Flame

Advantages

- Suitable for various metals: Almost all the commercial metals can be welded using oxyacetylene flames.

- Cost-efficient: Low cost of equipment used for oxyacetylene welding flame.

- High welding speed: The speed of welding in the case of oxyacetylene welding is high, increasing portability.

- Easy to learn and master: You can learn easily how to control the amount of oxygen and acetylene in the flame

- Multiple operations: Suitable for welding, cutting, and preheating operations.

- No electricity required: Oxyacetylene flame operations are suitable for remote places with no electric supply.

Disadvantages

- Surface finish: Results in rough surfaces after welding, requiring surface processing.

- Wide heat-affected zone: The heat produced is not concentrated at a single point. This results in the generation of thermal cracks and thermal stress development on the workpiece.

- Not suitable for thick materials: You cannot weld very thick materials as it cannot heat very thick cross-sections.

- Slow cooling rate: Gas welding processes provide quite a low cooling rate is relatively low, which may affect the production rate.

Welding Flames in MAPP Gas welding

Flame adjustment is the most important factor for successful welding or brazing with MAPP gas. There are three basic MAPP gas flames: carburizing flame, neutral flame, and oxidizing flame, just like other gas welding processes.

A carburizing flame with MAPP gas looks pretty much the same as acetylene. It has a yellow feather on the end of the primary cone. Carburizing flames are a result of oxyfuel ratios around 2.2:1 or lower.

As oxygen is increased, or the fuel is turned down, the carburizing feather disappears. When the feather disappears, the inner flame becomes deep blue. This type is known as a neutral flame for MAPP gas welding.

Increasing the oxygen flame produces a lighter blue flame, a longer inner cone, and a louder burning sound. This is an oxidizing MAPP gas flare.