Every seasoned welder will tell you that skills are not the single most important thing when welding aluminum. It takes a really good welding machine and proper equipment to do the job well.

Aluminum is everyone’s go-to material when it comes to fabrication due to its massively good looks, immense corrosion resistance, and lightweight properties.

![Best Welder For Aluminum - MIG/TIG/MP & AC/DC [2025] 1 featured image for best welder for aluminum article](https://weldingpros.net/wp-content/uploads/2022/10/featured-image-for-best-welders-for-aluminum-article-1024x563.webp)

But it can be a hell to weld and an utter nightmare if you are not prepared for it. During my time as a welder, I have created a lot of aluminum scrap while learning how to weld aluminum. But I also had a chance to test out a whole lot of welders. So I can tell you that picking up a good one breeds massively better results than doing it with any old welder.

Nobody goes into a gunfight sporting a knife, do they? You certainly can’t do proper MIG and TIG welding aluminum with a rust bucket.

For that reason, I went over a whole bunch of MIG and TIG welding machines and created a list of the ones I deem the fittest for aluminum welding. Hope you enjoy it and find it helpful during your hunt for a good welder.

Best Welder For Aluminum comparison table

| Welder Image | Name | Voltage inputs | Output Current Type | Amperage Output | Duty Cycle | Welding Process | Check Price |

|---|---|---|---|---|---|---|---|

![Best Welder For Aluminum - MIG/TIG/MP & AC/DC [2025] 2 AHP AlphaTIG 203Xi 200 Amp](https://weldingpros.net/wp-content/uploads/2022/10/AHP-200-Amp-Alpha-TIG-203Xi-TIG-e1665555452229.webp) | AHP AlphaTIG 203Xi 200 Amp | 110/220 V, 60 Hz | AC/DC | 10-200 A | Rated Output at 60% Duty Cycle 200 A | TIG/Stick | Check Current Price Amazon |

![Best Welder For Aluminum - MIG/TIG/MP & AC/DC [2025] 3 Yeswelder MIG-250 Pro image](https://weldingpros.net/wp-content/uploads/2022/10/YesWelder-250A-Aluminum-MIG-Welder-Spool-Gun-Compatible-1.webp) | YesWelder MIG-250A Pro Get 10% Off With Coupon: “-10% WELDPROS” | 220/230/240V 60 Hz | DC | 30-250 A | Rated Output at 60% Duty Cycle 250 A | MIG/TIG/ Stick/FC | Check Current Price YesWelder |

| ESAB Rebel EMP 205ci AC/DC | 120/230 ± 10% VAC, 50/60 Hz | AC/DC | 5-235 A | Rated Output at 60% Duty Cycle 125 A | MIG/FC/ Stick/TIG | Check Current Price Northern Tool |

![Best Welder For Aluminum - MIG/TIG/MP & AC/DC [2025] 5 Lincoln Electric POWER MIG 210 MP Multi-Process Welder](https://weldingpros.net/wp-content/uploads/2022/10/Lincoln-Electric-POWER-MIG-210-MP-Multi-Process-Welder-Aluminum-One-Pak-K4195-1-1-e1665555813571.webp) | Lincoln Electric POWER MIG 210 MP Multi-Process Welder | 115/230 60Hz | DC | 20-220 A | Rated Output at 25% Duty Cycle 200 A | MIG/FC/ TIG/Stick | Check Current Price Amazon |

![Best Welder For Aluminum - MIG/TIG/MP & AC/DC [2025] 6 Miller Syncrowave 210 TIG MIG Spoolmate 150](https://weldingpros.net/wp-content/uploads/2022/10/Miller-Syncrowave-210-TIG-MIG-Spoolmate-150.webp) | Miller Syncrowave 210 TIG MIG Spoolmate 150 | 110/115/125 V 208/220/230/240 V 50-60 Hz | AC/DC | 5-210 A | Rated Output at 60% Duty Cycle 125 A | MIG/FC/ Stick/TIG | Check Current Price Amazon |

Best Welder for aluminum reviews

Aluminum is one of the most favored materials used in fabrication. It is light, non-corrosive, and very appealing to the eye. Unfortunately, all those advantages are the reason why aluminum is a bit tricky to weld if you don’t know what you are going up against.

The right welder makes a whole lot of difference. So here are a few that you might consider perfect for the job.

1. AHP AlphaTIG 203Xi – Great Value Aluminum Welder

![Best Welder For Aluminum - MIG/TIG/MP & AC/DC [2025] 7 ahp alphatig 203xi](https://weldingpros.net/wp-content/uploads/2022/10/ahp-alphatig-203xi-welder-1004x1024.webp)

If you ever wanted an aluminum TIG welder but couldn’t afford one, the AHP AlphaTIG 203Xi can be a great first-ever TIG welder choice.

This one is really similar to the Harbor Freight ProTIG 200, which itself is a copy of Lincoln Squarewave. But comparing these three, AHP stands out with the obvious advantage – the TIG duty cycle. It’s rated and proven at 60%, as opposed to the 20-25% that Harbor Freight has.

AlpaTIG 203Xi is quite capable of TIG welding steel alloys and aluminum, particularly as it has AC capabilities and a pulse welding feature to boot.

Looking at the AHP lineup, AlphaTIG 203Xi is an improved version of the 2018 Alpha TIG machine many welders loved. While the package content remained pretty vast, with a comfortable TIG torch, regulator, and foot pedal, the new control panel features a large, high-visibility LCD color display.

Many features, such as a pulse rating of 0.5 to 150 Hz, AC balance, or high-frequency start, will help you TIG weld aluminum with ease. In addition, you can input parameters such as ramp up, ramp down, or peak amperage to get the best results and avoid wrapping thin material.

The downsides that I was able to notice are that the gauge in the flow meter is not so accurate, and the foot pedal is not really ergonomic. In addition, the AHP AlphaTIG 203Xi only goes down to 10 amps, so don’t expect any professional micro-TIG aluminum work.

Read more in this detailed review.

Pros & Cons Summarized

Pros

- Great duty cycle compared to similar price-range machines

- AC unit with pulse makes welding aluminum easy

- Noticeable improvement over older versions of the welder

- Easy HF start control

- Offers great value for money spent

- You can add a gas lens to get into tight spaces

Cons

- Operates down to 20 amps (AC), so you cant work with really thin materials

- Some items in the package are pretty bad

Specifications

- Process: TIG (GTAW) Stick (SMAW).

- Weld Thickness: Plain steel – 24 ga. – 3/8 in.

- Weldable Materials: Steel, Aluminum, Stainless Steel

- Input Voltage: 110/220 V, 60 Hz.

- Input Phase: 1-phase

- Current: Alternating/Direct current

- Minimum Amp Start On DC/AC: 5A/20A

- Amperage: TIG 5/20 A – 200 A.

- Pulse Frequency Range: AC: .5-150Hz; DC: .5-250Hz

- Rated Output: 200 A @ 60% duty cycle.

- Weight: 40 lbs.

2. YesWelder MIG-250A Pro – Best Aluminum Welder for Money

![Best Welder For Aluminum - MIG/TIG/MP & AC/DC [2025] 8 YesWelder 250A Aluminum MIG Welder Spool Gun Compatible 1 1](https://weldingpros.net/wp-content/uploads/2022/10/YesWelder-250A-Aluminum-MIG-Welder-Spool-Gun-Compatible-1-1.webp)

The YesWelder MIG-250A Pro is definitely the best aluminum welder for the money you pay for it that I was able to find. It comes with excellent build quality (sturdy designed casing) and an advanced synergic system.

How they were able to make it available for this kind of price is beyond me.

Unfortunately, it isn’t compatible with a spool gun, but it is capable of aluminum MIG welding.

It is a DC unit so you can’t TIG weld aluminum. It can weld it with MIG only. By making all the proper settings the welder is capable of producing a very nice bead.

Some other advanced capabilities are a hot start, long arc adjustment, and anti-pouring. Unfortunately, it can be a bit tricky to set as the instruction manual is hard to understand.

![Best Welder For Aluminum - MIG/TIG/MP & AC/DC [2025] 9 Yeswelder MIG Pro 250A MIG Welder Wire feed sistem](https://weldingpros.net/wp-content/uploads/2020/01/Yeswelder-MIG-Pro-250A-MIG-Welder-Wire-feed-sistem.jpg)

If you haven’t used any of these features before and are an inexperienced welder, you might have problems setting everything properly.

This MIG welding aluminum unit provides multifunctional capabilities, and has a decent number of settings, but the noticeable thing is the 250 amps of welding power it can produce at an amperage of 60% duty cycle. That is, in my opinion, a great value considering the low price point for a inverter technology welder.

Read more about this versatile welder.

Pros & Cons Summarized

Pros

- Best for money on the market

- Sturdy design and synergy control for beginners

- Hot start, long arc adjustment, and anti-pouring features provide smooth bead

- Decent drive system prevents wire tangle

- Lightweight IGBT technology increases portability

- Plenty of great features for the price

- Not compatible with Spool gun, but can MIG weld aluminum

- Super easy to set up and weld out of box

Cons

- DC unit which can’t TIG weld aluminum

- Poorly written instruction manual is almost useless if you are beginner

- TIG torch is not included

Specifications

- Process: Flux Cored (FCAW), MIG (GMAW), STICK (SMAW), TIG (GTAW)

- Weld Thickness: Mild Steel – 1/4 inches to 3/8 inches

- Weldable Materials: Steel, Aluminum, Stainless Steel

- Input Voltage: 220/230/240 V. 60 Hz

- Input Phase: 1-phase

- Current: DC only

- Amperage: MIG 30-250A, TIG 10-250A, Stick 20-225A

- Rated Output: MIG 60% 250A , Lift TIG 220A 60%, SMAW 250A 60%.

- Wire Range: 025”-.035” (0.6-0.9mm) solid steel, .030”-.035” (0.8-0.9mm) Flux-Cored

- Weight: 34 lbs.

3. ESAB Rebel EMP 205 AC/DC Multi-Process Welder

![Best Welder For Aluminum - MIG/TIG/MP & AC/DC [2025] 10 image of esab rebel 205ic](https://weldingpros.net/wp-content/uploads/2021/09/esab-rebel-205ic-mp-welder.webp)

What I really like about the ESAB Rebel 205 multi-process welder is its exceptional build quality. Not only that, but it comes with a 100-day “refund or replaces” guarantee. It also suits beginners, has an intuitive display panel, a glove-friendly job dial control, and the ground and foot pedal are fine quality, which you rarely see on these type of machines.

Unfortunately, the price is a bit high, even for a welder that is capable of doing, stick, MIG, and TIG welding. But it makes up for it, since manufacturer included a ton of accessories that are enough for a small, home fabrication shop. The MIG gun is solid and can fit a large spool of steel wire. The stinger is also of good build quality and there is a mid-level TIG torch thrown in as well.

MIG welding works well for indoor use with ArCo2 shielding gas and fluxed core are there for outdoor work. The DC TIG feature is going to be mostly used for stainless steel and mild steel metals, but the AC TIG is there for aluminum welders.

The thing I am concerned about the most here is the price. It might turn away a lot of people. But I think that the price is okay since you can start working off the bat, no settings needed. Also, unit can weld aluminum alloys, even at 120amps.

Read more about this high-end welder for aluminum.

Pros & Cons Summarized

Pros

- Sturdy and exceptional build quality increases durability

- Beginner-friendly, fine controls, easy to adjust and efficient

- Package includes everything you need for a small home repair shop

- High quality stinger and MIG gun

- Decent torch with flexible head, feeds electrode well enough

- Multi process unit used to weld different metals: alloy steel, galvanized steel, tool steel, aluminum, brass, bronze and copper

- Settings adjust to present welders needs

Cons

- Expensive

Specifications

- Process: AC/DC TIG (GTAW), DC Stick (SMAW), MIG, FCAW

- Weld Thickness: Can weld up to 24 ga., 3/8 in. plates

- Weldable Materials: Steel, Aluminum, Stainless Steel

- Input Voltage: 120/230 ± 10% VAC, 50/60 Hz

- Input Phase: 1-phase

- Current: Alternating/Direct current

- Amperage: 5 – 235 A

- Rated Output: 125 A / 15.0 V @ 60% Duty Cycle

- Weight: 49 lbs.

4. Miller Syncrowave 210 TIG Aluminum Welder

![Best Welder For Aluminum - MIG/TIG/MP & AC/DC [2025] 11 miller syncrowave 210 welder](https://weldingpros.net/wp-content/uploads/2021/09/miller-syncrowave-210-welder.webp)

The MIller Syncrowave 210 is not just a great home machine, but also a step up in quality compared to some other enter-level welders.

It basically allows you to work on 1/4 steel and aluminum and at 210 amps.

It has excellent build quality as well and I was also able to notice that Miller updates their products as they have improved their TIG welding programs and continue to add new modes on their products.

Even though the Syncrowave 210 is advertised as a multi welding process machine, I would not call it as such. It is one of the more capable TIG welders for aluminum and can even stick weld.

Unit goes down to 5 amps, which means you can easily weld thinner metals at the same time. As far as MIG goes, I would rather recommend using a Millermatic 210 MIG welder instead, but Spoolmate 150 spool gun which helps you weld with ease.

Compared to the 200 one, the 210 does offer more power and an improved duty cycle. I would say that if you are planning on doing some MIG welding and if your aim is to specifically weld aluminum, the Miller Syncrowave 210 with Spoolmate 150 deserves a go.

Pros & Cons Summarized

Pros

- Superior quality Miller build with durable commands

- Improved TIG welding capabilities provide best results

- Improved duty cycle over Syncrowave 200 increases versatility

- MIG welding capability is greatly increased by Spoolmate 150 spool gun

- Can easily weld up to 1/4 (6.4 mm) aluminum and steel

- Goes down to 5 amps which can be used to weld 0.020 in (0.5 mm) thin materials

Cons

- MIG welding without spool gun is limited

- Massive welder weighing 139.5 lbs. but still portable

- Expensive

Specifications

- Process: MIG, Flux-Cored, DC Stick, AC/DC TIG

- Weld Thickness: 0.020 in. – 1/4 in.

- Weldable Materials: Steel, Aluminum, Stainless Steel

- Input Voltage: 110/115/120 V; 208V 220/230/240 V 50-60 Hz

- Input Phase: 1-phase

- Current: AC/DC

- Amperage: 5-210 A

- Rated Output: 125 A at 15 V, 60% duty cycle

- Weight: 139.5 lbs.

5. YesWelder YWM211P – Duble Pulse MIG Welder For Aluminum

![Best Welder For Aluminum - MIG/TIG/MP & AC/DC [2025] 12 yeswelder ywm211p](https://weldingpros.net/wp-content/uploads/2022/08/yeswelder-ywm-211p-mig-welder-1024x1024.webp)

The YesWelder YWM-211P is the latest addition to a YesWelder line-up of feature-packed budget welders. This one offers explicitly double pulse MIG welding.

This technology is still somewhat new in the welding industry. It’s not widely accepted, so many people still haven’t caught on to the benefits.

Additional control over the pulsing waveform lets you manage heat input exceptionally well and have two very different pulses.

YesWelder YWM-211P is also a multi-process welder. So, besides double pulse MIG, you can also use DC TIG and stick welding. However, the DC TIG function is rather basic, and it doesn’t support a foot pedal control, and the TIG torch is not included.

While you cannot use this welder to TIG weld aluminum, YWM-211P is spool gun ready. Therefore, you can use it to MIG weld aluminum, and with pulse and double pulse options, you can even get TIG-like welds aesthetically wise.

With a maximum output of 200 amps, YWM-211P is quite a capable welder you can use for your everyday light to medium-duty projects. Dual voltage increases versatility, and you can weld extended periods with a rated duty cycle of 60% at maximum output. Comparison-wise, most brand-name MIG welders, such as Lincoln Handy MIG, or Miller Millermatic, offer a 20-30% duty cycle.

As a beginner, you can use the Synergic MIG option, where the welder automatically adjusts voltage and wire feed speed according to input data. Nonetheless, for best results, you can perfectly adjust double pulse, 2T/4T mode, or save up to 10 presets, making everyday welding easier.

Read more about this double-pulse welder.

Pros & Cons Summarized

Pros

- Multi-functional welder

- Pulsed and double-pulsed MIG welding for excellent aluminum results

- Synergic MIG controls for beginners

- Can MIG weld aluminum with an optional spool gun

- High-rated duty cycle

- Excellent command over the entire welding process

- Memory mode can store up to 10 welding presets

Cons

- DC-only machine, not suitable for TIG weld aluminum

- TIG torch is not included

- Spool gun for aluminum is sold separately

Specifications

- Process: Flux Cored (FCAW), MIG (GMAW), STICK (SMAW), TIG (GTAW)

- Weld Thickness: Aluminum Up to 1/4″

- Weldable Materials: Steel, Aluminum, Stainless Steel

- Input Voltage: 110/220V 50/60 Hz

- Input Phase: 1-phase

- Current: DC only

- Amperage: MIG 30-200A, TIG 10-200A, Stick 20-180A

- Rated Output: MIG 60% 200A ,TIG 200A 60%, SMAW 180A 60%.

- Wire Range: 025”-.035” (0.6-0.9mm) solid steel, .030”-.035” (0.8-0.9mm) Flux-Cored

- Weight: 39.5 lbs

6. Everlast PowerTIG 185DV TIG Aluminum Welder

![Best Welder For Aluminum - MIG/TIG/MP & AC/DC [2025] 13 image of everlast power tig 185DV](https://weldingpros.net/wp-content/uploads/2021/09/everlast-powertig-185-d.webp)

The Everlast PowerTIG 185DV is your typical hobby welder. You are not getting anything extremely special but you are getting your money’s worth.

It can weld aluminum and stainless steel alloys really nice. However, you better use it for the aluminum thickness of .060 to .187. and not .020 as specified. I think the real sweet spot for welding aluminum is in the .065 to .125 range.

It is definitely not the best for welding aluminum below .040 but is still enough based on the price.

I wouldn’t recommend it for thicker material, as it would be pushing the machine to the point of overheating, at least not without a water-cooled system.

The duty cycle is also fine for a majority of projects. The current goes as low as 20 amps at AC, which doesn’t make it suitable for really thin aluminum.

I found that many people had problems with the regulator and complained about it to customer service, which didn’t do their part to help. It also does not come with a foot pedal, and all the added accessories are pretty bad, except the ground cable and the torch. But all in all, a simple TIG welder for basic use is more than capable of its price.

Pros & Cons Summarized

Pros

- Great duty cycle compared to similar machines

- AC unit with pulse makes welding aluminum easy

- Noticeable improvement over older versions of welder

- Easy HF start, can make 1/4 single pass on alloy

- Offers great value for money spent

- You can add gas lens to get into tight spaces rapidly

Cons

- AC only goes down to 20 amps which doesn’t make it suitable for welding thin materials

- Keep in mind that most of the items in the box are pretty bad

Specifications

- Process: AC/DC TIG (GTAW), DC Stick (SMAW)

- Weld Thickness: 1/4 weld on single pass on alloy, 5/8 Steel

- Weldable Materials: Steel, Aluminum, Stainless Steel

- Input Voltage: 110/220 V, 60 Hz.

- Input Phase: 1-phase

- Current: Alternating/Direct current

- Amperage: TIG 5 A – 185 A.

- Rated Output: 200 A @ 60% duty cycle.

- Weight: 69 lbs.

7. Lincoln Electric Powermig MP 210 – Premium Welder for Beginners

![Best Welder For Aluminum - MIG/TIG/MP & AC/DC [2025] 14 image of lincoln electric powermig 210 mp](https://weldingpros.net/wp-content/uploads/2021/08/Lincoln-Electric-Powermig-210-Mp.webp)

If you are new to welding aluminum and don’t really intend to become a professional in the future, the Lincoln Electric Powering MP 210 is in my opinion a wise investment for a starter in the business.

That said, it is a very solid, well-built MIG welding machine that even comes with a stick setup. It can be used to weld stuff of 045, 035 thickness, but has added rollers for thin aluminum sheeting.

I was really impressed by the wiring and the components inside, as you only find those in a professional MIG welder. However, it only has a DC TIG function and no AC TIG. It can be used on steel and stainless steel, though.

The way this machine is able to weld aluminum can be compared to the Millermatic 200 or the L Tech Migmaster 250. Some people will find that the pre-adjusted settings are too hot for the base aluminum that you work on, so you better do it manually per your liking. It is quite okay to use the 0.035 welding wire on it and you can even run it at 220v. But the most impressive part is the duty cycle, which allows you to weld for about 30 to 45 minutes without a hitch.

With Magnum PRO 100SG Spool Gun included, and all the fine tune options, it is the perfect unit for aluminum welding. I find this unit quite lightweight and portable, so you can easily move it around the garage, and I believe it will fit your skills.

Pros & Cons Summarized

Pros

- Multi process unit perfect choice for beginners, but can be suitable for professionals

- High quality Lincoln components and build

- Magnum PRO 100SG Spool Gun included

- Great aluminum welding ability, but also efficient with different metals

- Lightweight and portable, but durable design

- Compact unit that wont take too much space in your garage and its easy to pack

Cons

- Cant TIG weld aluminum

- Pre-adjusted settings can be a bit hot for aluminum

Specifications

- Process: MIG, Flux-Cored, DC Stick, DC TIG.

- Weld Thickness MIG: 5/16 in. mild or stainless steel or aluminum up to 3/16 in.

- Weld Thickness FC: (Self- and Gas-shielded): Tackle the biggest jobs

- Weld Thickness Stick: Can handle up to 5/32 in. stick welder electrodes

- Weld Thickness TIG: Enabled by Touch Start TIG® technology

- Weldable Materials: Steel, Aluminum, Stainless Steel

- Input Voltage: 115/230/1/60Hz

- Input Phase: 1-phase

- Current: DC only

- Amperage: 120V: 20-140 Amps DC, Max. OCV: 56, 230V: 20-220 Amps DC, Max. OCV: 56.

- Rated Output:120V: 100A/19.0/40%duty cycle./230V: 200A/24V/25% duty cycle.

- Wire Feed Speed: 50-500 ipm (1.3-12.7 m/min).

- Weight: 40 lbs.

8. Hobart Handler 210 MVP – Premium Welder for Hobbyists

![Best Welder For Aluminum - MIG/TIG/MP & AC/DC [2025] 15 hobart handler 210 mvp](https://weldingpros.net/wp-content/uploads/2021/08/Hobart-500553-Handler-210-MVP-MIG-Welder.webp)

The Hobart Handler 210 MVP is a pretty nifty machine and holds a variety of advantages compared to its Hobart Handler 140 counterpart. I

f you are searching for a welding machine that adds more power this is the one to choose. I would place it in the premium range for hobby or DIY users, but it can work perfectly well for pros that like taking serious projects on the side.

This machine is perfect for MIG welding aluminum with spray transfer as with the offered 200 amps it is at the bottom end for welding thicker pieces. Once you match it with SpoolRunner 100 spool gun, you can go through 1/4-inch aluminum alloys in minutes.

The 110/220v dual voltage feature makes it a useful flux-core field welder. But at around 80 lbs, it is not as lightweight as you would think. It can be hard to carry. I also liked its performance as the arc characteristics are really good.

I noticed an improvement compared to the last model as Hobart has added solid metal drive rolls instead of the plastic ones as before, so the feeder runs smoothly. Unfortunately, it is a single drive roll instead of double drive rolls due to the material change. I also found that changing the wire in the spool gun is a bit difficult, but once you get the hang of it, you will have no issues.

All in all, a fine aluminum welder for a person who needs a solid machine on a budget. It costs more than the MigMax 215 but is well worth the added money.

Find out more about Hobart Handler 210 MVP.

Pros & Cons Summarized

Pros

- Welding is smooth, arc quality control provides stability

- Cost-effective, multi position voltage control

- Noticeable improvement over Hobart Handler 140

- Industrial cast aluminum drive system reduces chances for wire to piles up and great for softer aluminum wires

- Includes dual gauge regulator, power cord, and ground clamp cable

- When matched with spool gun, it can weld aluminum easily

- Easy to set up and use

Cons

- Expensive

- Heavy

- Changing spool gun wire can be difficult

- Single metal drive roll

Specifications

- Process: Flux Cored (FCAW), MIG (GMAW)

- Weld Thickness: Mild Steel – 1/4 inches to 3/8 inches

- Weldable Materials: Steel, Aluminum, Stainless Steel

- Input Voltage:110/115/120 V, 220/230/240 V. 60 Hz

- Input Phase: 1-phase

- Current: DC only

- Amperage: 115 V: 25–140A, 230 V: 25–210A

- Rated Output: 115 V, 90A @ 20% duty cycle/230V, 150A @ 30% duty cycle

- Wire Feed Speed: 40 IPM – 770 IPM

- Weight: 79 lbs.

Why is Aluminum So Difficult to Weld?

The main characteristics that make aluminum so hard to master are that it is soft, sensitive, and has an aluminum oxide coating.

Additionally, it is widely know that aluminum is highly intolerable to impurities, and contamination of the puddle can lead to porosity and weak welds.

Before welding, the surface and work pieces must be treated by a chemical etch process or cleaned mechanically with a wire brush

Aluminum also has high thermal conductivity coupled with a lower melting point, resulting in a small window of workability. One small mistake can lead to burn-through.

Aluminum Welding Processes

The main three welding processes for aluminum include TIG welding, MIG welding, and Torch welding, and it doesn’t really matter which one you choose, as long as it is efficient. You should opt for the one that suits you the best, and you can’t make a wrong choice.

Gas Tungsten Arc (TIG) Aluminum Welding (GTAW)

TIG welding is one of the favorite processes used by aluminum welders. Welding aluminum requires a lot of heat which TIG machines are known for. TIG welders require equipment with a constant current with AC capabilities and pure Argon as shielding gas, and a proper filler rod is often required.

Mechanical welding wire feed is not needed. Instead, the welder feeds the filler rod precisely into the weld pool. AC TIG welding is extremely clean as the shielding gas helps in removing the aluminum oxide coating. Oxides can be removed by chemical processes, or by a wire brush, since they have higher melting point than base aluminum. Higher melting point surface can easily mess up your weld appearance completely.

Gas Metal Arc (MIG) Aluminum Welding (GMAW)

MIG welding is also a favored welding method for aluminum welding. MIG welders should come with both pulse welding or spray arc welding features. The former requires an inverter power supply, while the latter needs constant voltage.

MIG welding is a perfect welding method for working on thin materials, mostly because of the heat. The best shielding gas choice is 100% Argon, and you need to match the filler rod to the alloy grade of your base aluminum.

Torch Aluminum Welding

Torch welding is considered the most complicated way of welding aluminum that even experienced professionals avoid. Only dexterous welder is brave enough to try it as they have the skill to maintain complete control of the heat and penetration. Even though it is a forgiving welding method, melt through can occur commonly with torch welding. Keep in mind that even dexterous welder can’t predict the outcome.

What To Look for When Buying Welder for Aluminum (Best Welder for Aluminum Buyer’s Guide)

One has to be vary when looking for a machine that can weld aluminum. I have constructed a list and now I am going to tell you how to approach buying a welding unit and what’s the key to look for when doing so.

Alternating Current or Direct Current

Using alternating current (AC) is more preferable to direct current (DC) when welding aluminum. DC creates a lot of heat, which immediately eliminates it as a viable welding method for aluminum. But if you really have to use DC, it is recommended that you switch polarity from revers to straight. You will not be able to clean the oxide layer well but will get a stable arc that is easier to control.

Output Power

Welders need to look for machines that are capable of producing the highest welding ability, usually determined by output power. However, 1/4 and 1/16 cutting ability is more than enough for beginner welders. Additionally, it is also important to operate at low amperage. It allows you to maintain a stable arc below 10 amps, adds more versatility, and provides better bead appearance.

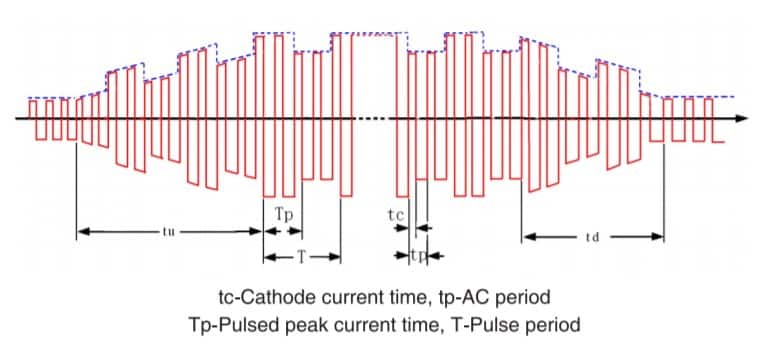

Pulse Feature

Heat control is absolutely paramount when you weld aluminum. Having not enough heat in general cancause distortion and if you apply too much, you’ll have a burn through. The pulse welding feature constantly switches from high current to low, steadying the arc temperature and allowing the welder to cool down.

Rated Duty Cycle

The duty cycle is a rating that every MIG welder and TIG welder come with. It basically means how long a machine can continuously work without having to cool down. So a welder rated with a 30% duty cycle means your work is limited to 3 minutes before overheating. Too much heat can cause damage to your unit.

Welder Price and Budget

Sometimes it all comes to your budget. We can’t deny that the amount of money we have at our disposal will dictate which MIG welder we are about to buy.

Advanced features cost more and if you want AC DC TIG capabilities, dual voltage, and the latest inverter technology you have to spend quite a few bucks. Make sure your unit has all the needed protection (overload protection, overheat protection).

Machine prices can stretch from a few hundred to a couple of thousands. More expensive is always better, but that is not to say that there aren’t some great budget options out there.

Frequently Asked Questions

What is the best process to weld aluminum?

MIG and TIG welding are the most popular welding process to weld aluminum, while torch welding is considered the most difficult one.

Can you TIG weld aluminum?

Yes, you can. Make sure to get the equipment capable of AC TIG welding and a 100% Argon as a shielding gas, as it needs to be extremely clean.

Do you weld aluminum better with TIG or MIG?

Both processes have their advantages and disadvantages and it often comes to the skill of the welder.

Do you weld aluminum better with TIG or MIG?

Aluminum is a soft and sensitive material. It has higher conductivity and a lower melting point, so the workability window is small. Aluminum oxides can be a bit hard to break through and is susceptible to impurities.

Conclusion

This would be everything I have for you. I have added my thoughts and created a list of best welders for aluminum and basically explained how I got to it with a buyer’s guide. Now it is up to you to determine the best way of going about it and buying a welder. If you require any more information, please contact me, I’ll be more than happy to answer your questions and help you decide. In the end, life is all about right decisions.