Welding terminology is complex, especially since many terms are used for different things.

So, to make your life easier we compiled the most complete welding terms list without going overboard with terms you are unlikely to ever need.

Our list is big, but if you master the terms below, you’ll never be confused when listening to oldtimers blab on their break.

Welding terminology 101

Welding terminology on – A

- Acetone: Acetone is a volatile and flammable liquid found in acetylene cylinders. It is used in the stabilization and dissolving of acetylene under high pressure.

- Acetylene: This highly combustible gas is composed of hydrogen and carbon and is used as fuel in oxyacetylene welding. All precautions must be followed when working with this gas.

- Active Flux: Active flux is a flux formulation that should produce a weld metal composition that depends on the welding parameters.

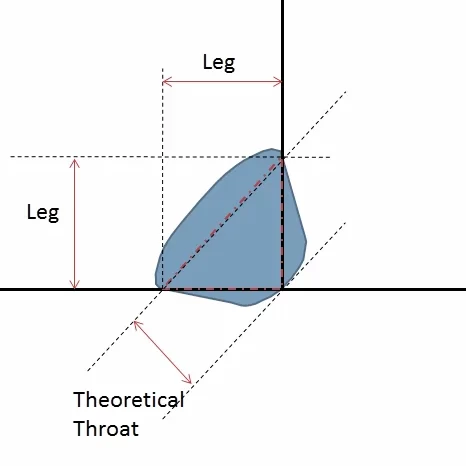

- Actual Throat: It represents the shortest measurement between the root of the weld and the face of the fillet weld.

- Aging: Keeping materials at room temperature after they have been subjected to heat treatment for the purpose of increasing dimensional stability or increasing their hardness and strength.

- AISI – American Iron and Steel Institute

- The American Iron and Steel Institute is an association of North American steel producers.

- Air-Arc Cutting: Air cutting process that cuts metal using the heat of the carbon arc.

- Air-Acetylene: A low temperature flare that is a product of acetylene burning with air instead of oxygen.

- Ampere – A: Ampere is a unit of electrical rate of flow. It is commonly referred to as the “current” and it is very important variable in welding.

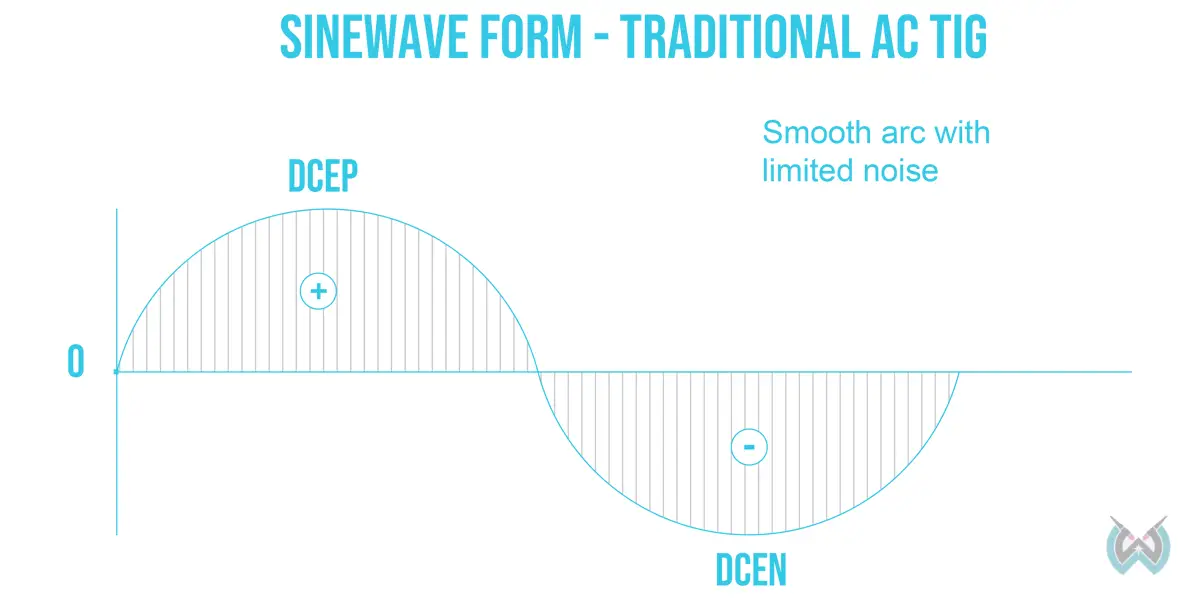

- Alternating Current (AC): An electrical current that reverses its direction at regular intervals. The current flows in one direction and then it reverses. In welding, this is associated with welding processes like AC TIG welding for example.

- Alloy: Alloy is a metal made from two or more elements. Common alloys in welding are nickel alloy for example.

- Ammeter: An instrument that measures electric current in amperes. Ammeter works by an indicator that gets activated with the movement of a coil in a magnetic field or as a result of the longitudinal expansion of the wire that carries the current.

- Annealing: Annealing is a process that reduces internal stress through the slow cooling of the metal. It makes the material softer and influences its ductility. Annealing is a cycle composed of heating and cooling but it is usually attributed to the cooling part with an emphasis on the slow cooling. Steel can be annealed for: stress removal, inducing softness, improving toughness, altering its ductility, for magnetic and electric reasons, altering the crystal structure, removing trapped gasses, and others.

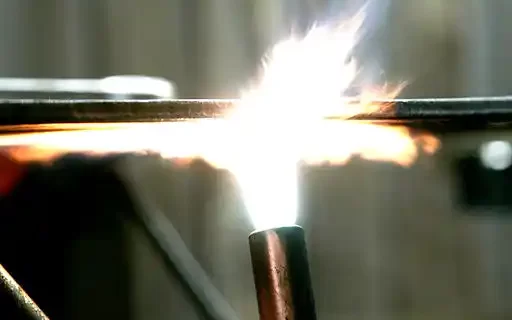

- Arc Welding: Arc welding is a very broad term that is used to describe many different types of welding processes. These processes have a common denominator which is the usage of an electric arc that creates heat. This arc melts the materials which are then joined together. Filler metals may be used but also pressure to weld pieces together.

- Arc Blow: When magnetic forces deflect the arc from its usual path we call it an arc blow.

- Arc Brazing: Brazing processes use an electric arc to create necessary heat. The arc is created between the arc welding electrode and base metal or between two electrodes.

- Arc Cutting: There are many different arc cutting processes and they all use an arc as a heat source to cut the base metal.

The arc is formed between the electrode and the base that is being treated. - Arc-Oxygen Cutting: A cutting process that is based on oxygen. It is used to cut metal by a chemical reaction of oxygen and a base metal at high temperatures.

- Arc Length: The measurement between the weld puddle and the tip of an electrode.

- Arc Voltage: The voltage of the active welding arc.

- Arc Weld Deposition Efficiency: This efficiency is calculated as a ratio between the filler metal deposited in the weld to the weight of filler metal that was melted.

- As Welded: This refers to the welded metal, joints and weldments condition after the welding is done and before any additional treatment of the metal like mechanical, thermal and chemical as examples.

- Atomic Hydrogen Welding: The fusion obtained in this arc welding process is a consequence of heating with an arc maintained between two metal electrodes in a surrounding of hydrogen gas.

- Autogenous: Refers to the welds that are made without any filler materials.

- Automatic Welding: Advanced welding method that uses welding equipment that is autonomous and can weld without the constant input by the welder/operator. This kind of automated welding equipment is capable of aligning joints too. It does so using automated sensing devices.

- Austenite: The nonmagnetic iron form. The austenite is characterized by a face-centered cubic lattice crystal structure. This iron form has a high solid solubility for carbon and alloying elements and is created by heating steel above the critical upper temperature.

- AWS – American Welding Society: American Welding Society is a non-profit organization founded in 1919. Its purpose is to advance the technology, science and application of welding, joining and cutting processes.

- AWS D1.1: Structural Steel Welding Code provided by AWS.

- Axis of a Weld: Axis of a weld represents a line in the length of a weld that is perpendicular to its cross section at its center of gravity.

Welding terminology on – B

- Base Metal: Base metal is the metal piece that you weld or cut i.e. metal plate, pipe, beam, etc.

- Backing: A piece of material placed at the root of the joint meant to support the molten metal while it cools. It’s especially useful with wide root gaps. The backing ring serves the same purpose, but it’s added to pipes.

- Back Weld: Welding pass from the opposite side of the joint’s face.

- Backhand Welding: A torch/gun manipulation method in which the torch is directed opposite of the welding progress. It is also referred to as the “pull gun technique.”

- Bare Electrode: Refers to the arc electrodes without coating.

- Bare metal arc welding (BMAW): An arc welding process that joins metal by heating them with an electric arc between a bare or lightly coated electrode. It doesn’t require shielding gas or pressure. But, this process is obsolete and not used anymore.

- Bevel Angle: Angle formed between two joint ends by beveling them with an angle grinder, oxy cutter, or a beveling machine.

- Bend Test: A destructive testing method where the tested welded metal is bent to a specified radius to determine the weld ductility and quality.

- Bevel: Bevel is an angled edge preparation.

- Bond: The adhesion of the filler welding metal and the base metal.

- Boxing: Continuation of the fillet weld as an extension of the principal weld.

- Brazing: Brazing is a welding process in which various joint configurations are formed with a nonferrous filler metal with a melting point below that of the base metal. So, the filler metal melts into the joint but the base metal does not.

- Break Test: A destructive weld testing method that requires breaking the welded joint and examining it its surfaces for defects.

- Burn-through: Often used term when you burn a hole in the metal as a result of excessive heat input.

- Bridging: A void near the root of the weld caused by poor penetration.

- Buckling: Metal distortion resulting from overheating the material.

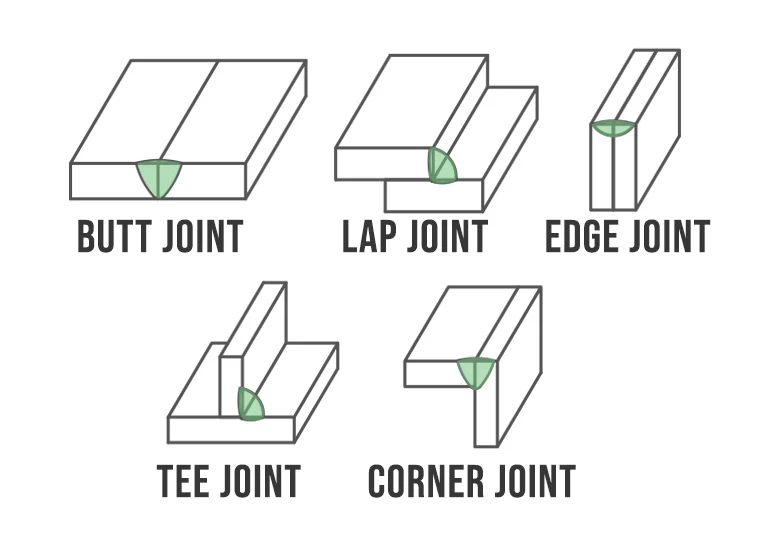

- Butt Weld: A weld made in the butt joint configuration. Two workpieces are placed in the same plane and welded in the joint between them.

- Buttering: A surfacing form in which one or multiple layers are deposited on the weld groove. It is used to provide a transition for subsequent completion of the joint.

Welding terminology on – C

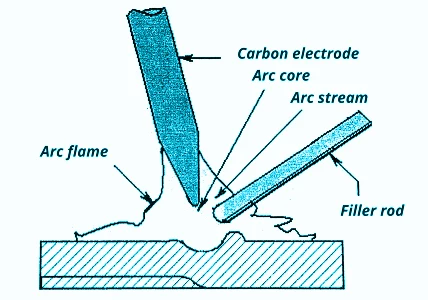

- Carbon-Arc Welding: Welding process in which an arc is formed between a carbon electrode and the base metal. It is less used today as more modern processes have taken over.

- Carbon-Arc Cutting: Same as the welding process above, the carbon arc cutting process cuts the metal with the arc formed between a carbon electrode and the work.

- Carbon Electrode: A carbon or graphite rod is used in carbon arc processes; it’s made out of carbon and may be coated with other materials like copper.

- Cascade Sequence: The longitudinal sequence of combined weld build-up deposited in overlapping layers.

- Case Hardening: Used to harden the metal surface by using inward diffusion with gasses or liquids before the heat is applied.

- Carburizing Flame: An oxyacetylene flame with an excess of acetylene gas.

- Carbide Precipitation: Also referred to as weld decay, carbon precipitation occurs with austenitic stainless steel which contains carbon in a supersaturated solid solution, making it unstable.

- Chamfering: A method of edge preparation.

- Coalescence: Coalescence occurs when metals fuse upon heating.

- Covered Electrode: Covered electrodes use a coating of paper, flux, asbestos or other materials to improve arc stability.

- Coated Electrode: Unlike covered electrodes, coated electrodes have a layer of flux that produces a shielding gas when the electrode is burned.

- Concavity: The perpendicular distance between the face of a concave weld and a line joining the weld toes.

- Convexity: The perpendicular distance between the face of a convex fillet weld to the line joining the weld toes.

- Composite Joint: This joint uses mechanical and thermal processes to join metal.

- Coating: A thin layer of material applied over the metal’s surface to prevent corrosion or to improve the mechanical characteristics of the base metal.

- Complete Joint Penetration: Joint in which the fusion takes place over the entire joint’s depth; the filler metal completely fills the groove and penetrates in the walls of the joint.

- Concave Fillet Weld: A fillet weld with a concave surface

- Constant Current (CC): Sometimes referred to as droopers, constant current welding machines use limited maximum short circuit current and have a negative volt-amp curve.

- Corner Joint: A joint formed by two elements intersecting at an approximately 90-degree angle; this joint is formed as a letter “L.”

- Critical Temperature: The temperature at which the welded material transitions fro one crystalline form to another.

- Crater: A depression left after you terminate the arc.

- Crack: Cracks are welding defects that can never be allowed. Cracks occur as fracture-type discontinuity with sharp tips and high length to width ratios.

- Current: Current is another name for amperage. It designates the electricity amount that flows through a conductor every second.

- Current Density: The amperes applied per square inch of a particular area.

- Constant Voltage (CV): Constant voltage power sources are used for conventional MIG (GMAW) welding with a short arc, globular, and spray metal transfer.

- Cylinder: Also referred to as gas bottle, a cylinder is a portable container used to store compressed shielding or welding gas.

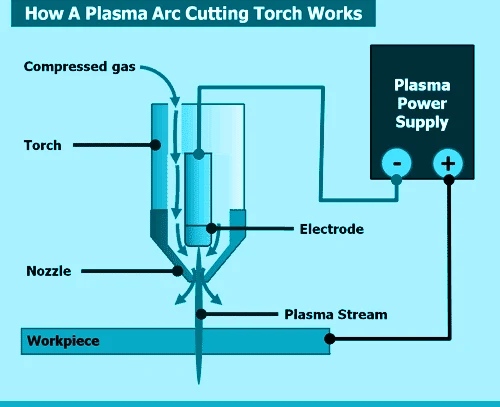

- Cutting Torch: A cutting torch term usually refers to the torch used for oxy-acetylene gas cutting but it may sometimes be used to define a plasma cutting torch.

- Cutting Tip: A torch tip used specifically for cutting metal.

Welding terminology on – D

- Defect: Welding discontinuity or discontinuities which render the welded product unable to meet minimum applicable acceptance standards or specifications. Sometimes one defect is enough to render the part invalid, while sometimes, a combination of multiple defects has a cumulative effect.

- Defective Weld: A weld with one or more defects that render it invalid.

- Depth of Fusion: The depth to which the weld fusion extends into the base metal or the underlying weld made in the previous pass.

- Deposited Weld Metal: Filler metal added during the welding procedure.

- Deposition Efficiency: The ratio between the deposited filler metal and the net weight of the consumed filler material.

- Destructive Testing: A weld testing method in which the welded part is destroyed in the process of weld quality testing.

- DIG: Dig helps during the stick arc welding process by providing additional amperage during the low voltage conditions. It helps prevent sticking the electrode and it’s also called arc control.

- DIE Welding: A forge welding process that uses a preheated die and applied pressure to create a fusion.

- Direct Current Electrode Negative (DCEN): The electrode in an arc welding process is attached to the negative terminal while the ground clamp is attached to the positive terminal.

- Direct Current Electrode Positive (DCEP): The electrode in an arc welding process is attached to the positive terminal while the ground clamp is attached to the negative terminal.

- Discontinuity: A discontinuity is not always considered a weld defect. It means that there is an interruption of the welded joint structure and of its properties. The weld may have metallurgical, physical, or mechanical discontinuities.

- Drag Angle: The travel angle when the welding gun/torch is pointing backward.

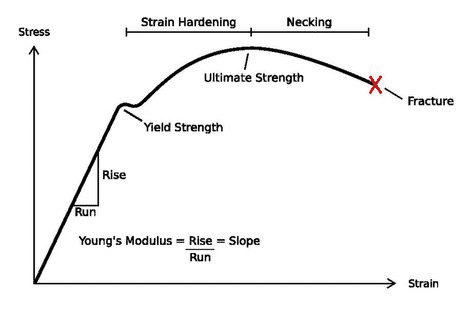

- Ductility: Mechanical property of a metal that allows it to be permanently deformed, stretched, or otherwise change its shape under tension load. Tensile tests determine the ductility of the metal. You can learn more about ductility in welding here.

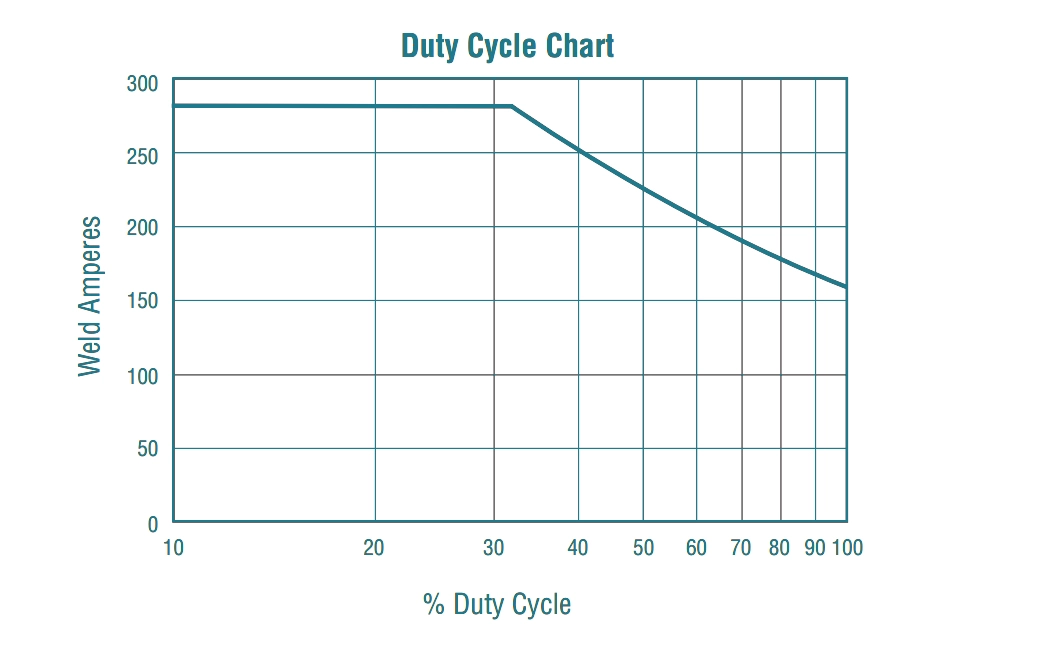

- Duty Cycle: Welding power sources are tested and rated to run at a specified current output for a duration of time in one 10-minute interval. This rating is called the duty cycle and its expressed in the percentage value of the 10-minute interval. Learn everything about the duty cycle here.

- Dye Penetrant Testing: A non-destructive weld testing method that uses dye to detect surface defects of a weld.

Welding terminology on – E

- Edge Preparation: A process of preparing the edge(s) of a joint before welding. It includes pre-cleaning and sometimes beveling the joint. Learn more about weld preparation here.

- Electric Arc: All arc welding processes use an electric arc to melt and fuse metals together. These include GTAW, GMAW, FCAW, PAW, MMA, and a few others.

- Electrode Extension (FCAW, GMAW, SAW): The length of solid wire (electrode) extending beyond the nozzle tip.

- Effective Weld Length: The length of correctly proportioned cross-section throughout the weld.

- Electrode: The electrode conducts the electric current into the metal. Some electrodes act as a filler metal and get consumed in the process, while others are non-consumable like tungsten electrodes in the TIG welding process.

- Effective Throat: The minimum distance from the weld root to its face without added reinforcment.

- Electrode Holder: A hand-held device that grips the electrode, holds it in place, and supplies the electrical current necessary to melt it.

- Electrode Lead: The cable connects the power source to the electrode holder.

- Etching: A process of preparing metal samples and welds for micrographic and macrographic examination.

- Electroslag Welding (ESW): A welding process that joins metal using molten slag which melts the filler metal and the workpieces to be joined. The slag protects the molten metal pool from contamination.

Welding terminology on – F

- Face Shield: Welding operators use face shields to protect eyes and face from sparks, metal debris, and other physical hazards in the work area.

- The face of Weld: The side of the weld from which the welding was performed.

- Face Reinforcement: Added reinforcement weld at the side of the joint where the welding was initially performed.

- Feed Rate: The rate of adding a filler material through a gun.

- Faying Surface: The surface of the member in close proximity to another member to which it should be joined.

- Ferrite: A pure form of iron characterized by a body-centered cubic lattice crystal structure. It exists below the lower critical temperature and is magnetic.

- Filler Metal: Added metal while welding, brazing, or soldering the joint.

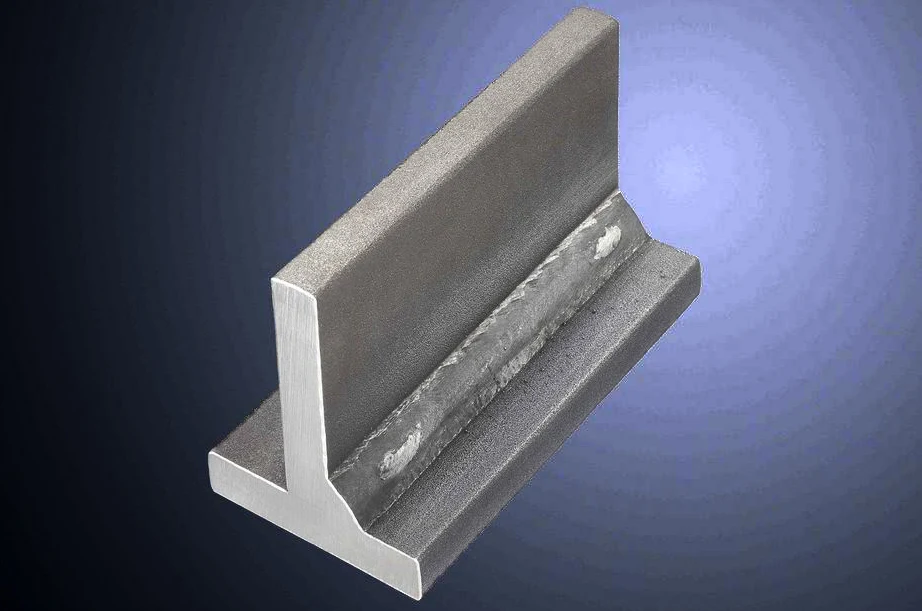

- Fillet Weld: The Fillet weld joins two pieces at an approximately 90-degree angle and fillet weld cross section is triangular.

- Flame Cutting: Typically used to describe a flame process that uses oxygen as fuel to cut metal.

- Flame Gouging: Similar to flame cutting, flame gouging uses oxygen fuel to create grooves in metal.

- Flame Hardening: Metal is hardened by heating it with an open flame and quickly quenching it.

- Flaw: Synonym for discontinuity.

- Flat Position Welding: Welding from above the joint — the weld face is horizontal.

- Flowability: Molten metal’s ability to flow or spread over the metal surface.

- Flux: The material used to prevent, dissolve, or facilitate the removal of oxides and other contaminants from a metal surface. Various flux compounds are also used to coat stick welding electrodes and to fill flux-cored wires.

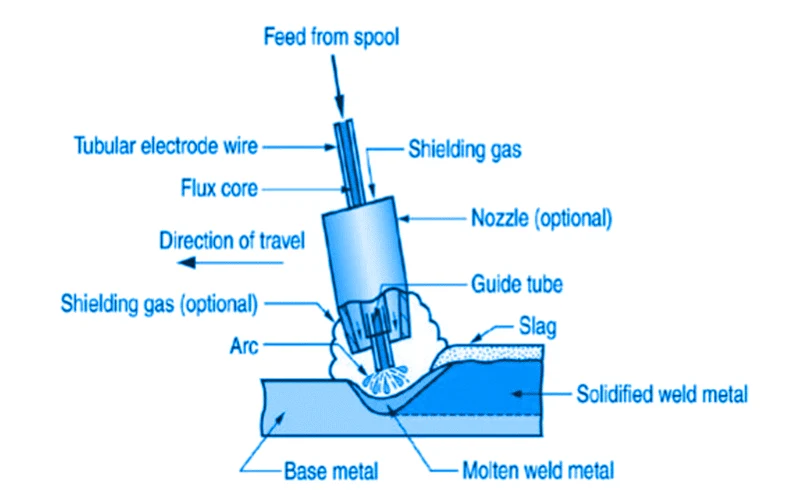

- Flux Cored Electrode: A type of tubular wire filled with flux compounds that release shielding gasses and shielding slag to prevent weld contamination. The core is also filled with arc stabilizing and deoxidizing agents.

- Flux Cored Arc Welding (FCAW): FCAW welding process uses flux-cored wire. The self-shielding flux-cored wire doesn’t require additional shielding, but the shielding flux-cored wire does. This welding process works well with rusted steel and welding outside, and it’s characterized by deep penetration.

- Flash Welding: A resistance welding process that produces fusion simultaneously over the entire area of the joining surfaces. It uses current flow resistance as the heat source and the application of pressure to complete the fusion.

- Flashback: It occurs when the flammable gasses burn back withing the torch or beyond the torch inside the hose.

- Flowmeter: Used as a shielding gas regulator.

- Forehand Welding: A welding technique in which the flare is directed against the base metal ahead of the laid weld.

- Fusion Welding: Any welding process that uses fusion to join the metal pieces.

- Fusion: Melting together the base metal and the added filler metal. But, fusion is also used to describe a process of joining metals by melting them together without filler metal.

- Fusion Zone: The Fusion zone is observable on the cross-section of the weld and represents the area of base metal that was melted in the welding process.

- Fusion Face: A base metal surface that’s melted while welding.

- Free Bend Test: Testing weld samples without a guide.

Welding terminology on – G

- Gas Pocket (Cavity): Occurs when gas becomes trapped inside a gas cavity. This causes porosity and makes brittle welds.

- Gas Welding: A welding process that melts metal together using a gas flame.

- Gas Carbon Arc Welding: An arc welding process that uses a carbon electrode to form an electric arc between the electrode and the work. The electrode is non-consumable, and the shielding gas needs to be inert like argon or helium. This welding process melts metal together with or without a filler metal.

- Gas Metal Arc Welding (MIG or GMAW): GMAW also referred to as MIG welding process, is an arc welding process that uses an electric arc between a consumable electrode (solid filler metal electrode – MIG wire) and the workpiece. Shielding gasses are carbon-dioxide and argon.

- Gas Tungsten Arc Welding (TIG or GTAW): GTAW, also called TIG welding process, is an arc welding process that uses a non-consumable tungsten electrode and inert shielding gasses like argon and helium.

- Globular Transfer: Metal transfer type in which the deposited molten metal is transferred via arc in large droplets.

- Gouging: Gouging forms a bevel or a groove in the metal by removing material.

- Groove: Opening or a channel between two metals that is to be filled with a weld.

- Groove Face: The joint surface of a part that forms a groove with another part.

- Groove Angle: The total included angle between the parts to be joined with a groove weld.

- Groove Radius: J or U-groove weld radius.

- Groove Type: The geometric configuration of a groove can be square, V, U, J, flare, and bevel groves. You can learn more about joint types here.

- Ground Connection: A safety connection that grounds the welding machine. NOTE: A cable that connects the welding machine (power source) and the ground clamp is correctly called workpiece connection. But, many welders use the term “ground” lead.

- Ground Clamp: The ground clamp is correctly called a work clamp. is used to complete the electrical circuit with the metal being welded.

Welding terminology on – H

- Hard Facing: A form of surfacing in which a cladding or coating is applied to the metal’s surface to reduce wear or degradation of the surface as a result of impact, abrasion, galling, cavitation, and erosion.

- Hard Surfacing; Using specialized wear-resistant alloys to clad the surface of a softer metal. Hard surfacing is often performed with specialized surfacing stick electrodes.

- Hammer Welding; Hammering two pieces of heated metal together in a forge welding process.

- Hand Shield; A hand-held shield that has a protective filter lens through which you should observe the electric arc. The shield protects the eyes and the face from dangerous infrared and ultraviolet radiation.

- Hardening; Any process that involves hardening the material. Usually, it refers to the process of quenching of certain iron-based alloys.

- Helmet; A welding helmet is used to protect the welder from IR and UV radiation. It can have a passive filter protection or an auto-darkening filter.

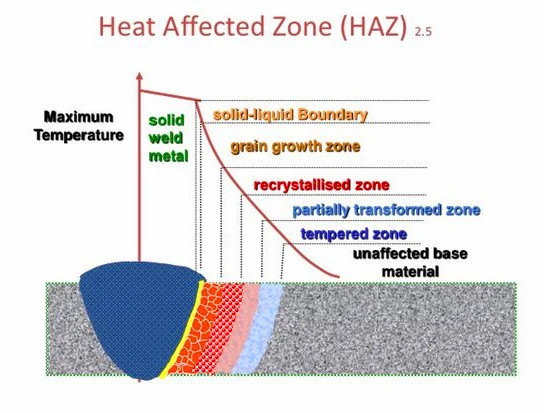

- Heat Affected Zone (HAZ); A zone near the welded joint that hasn’t been melted during the welding process but has had its mechanical properties altered.

- Heat Treatment: Refers to the heating and cooling processes pre and post-welding. Sometimes it’s necessary to preheat the metal to a certain temperature to achieve a quality weld. But, it may also be necessary to perform a post-welding heat treatment to achieve desired metal properties. You can learn more about heat treatment here.

- Horizontal Weld; A weld performed horizontally with a linear direction or inclined at an angle less than 45-degrees to the horizontal.

- High-Frequency (HF); A frequency higher than 50,000Hz. TIG welding machines often use an HF arc start for better weld soundness.

- Hertz; Often referred to as “cycles per second.” In the United States, the frequency of the alternating current is usually 60 hertz — meaning that the AC current alternates 60 times per second between positive and negative.

- Horn; Resistance spot welders use “horns” or electrodes that hold the welded part together while supplying current.

- Hydrogen Brazing; Brazing performed in a furnace with a hydrogen atmosphere.

- Hydromatic Welding; Also referred to as pressure-controlled welding, hydromatic welding makes spot welds in a sequence using more than one electrode under pressure.

- Hot Wire TIG (GTAW-HW); Hot wire TIG is an automated welding process that uses standard TIG technology coupled with an automated wire feeder that feeds the electrically hot (pre-heated) wire to the weld pool. Learn more about hot wire TIG in our article here.

Welding terminology on – I

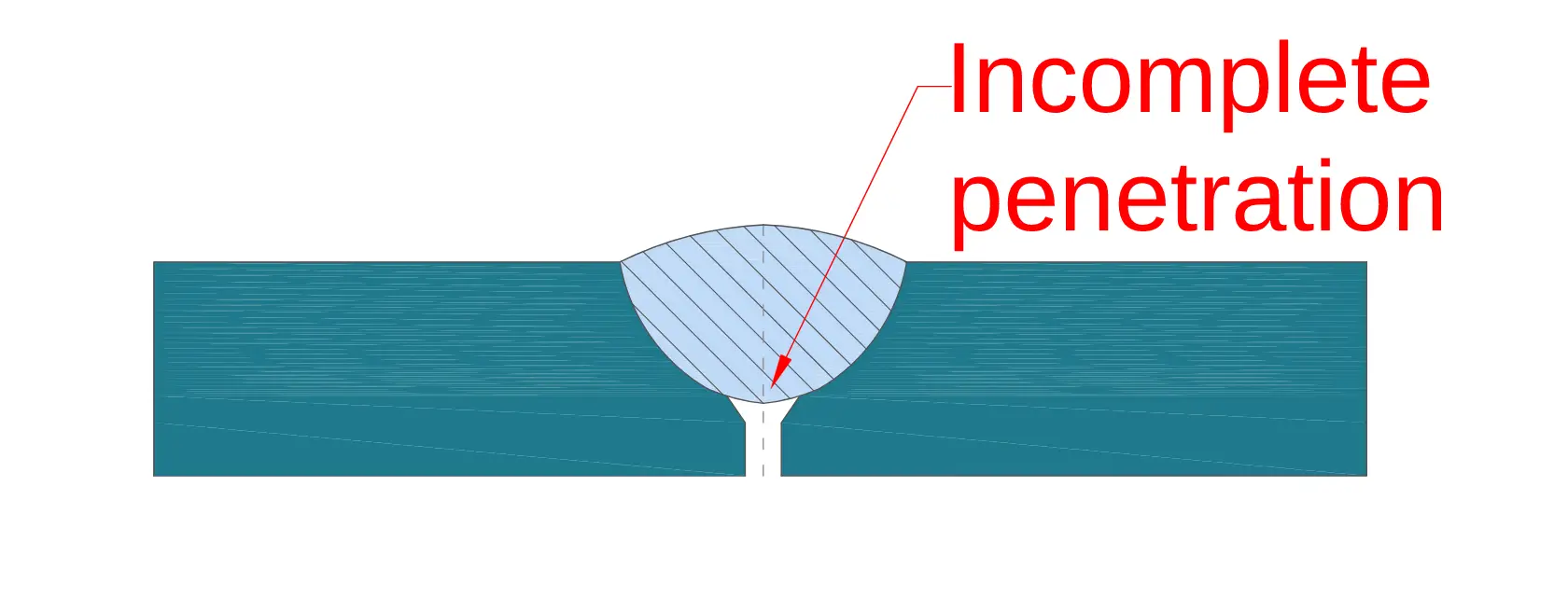

- Inadequate Joint Penetration; Poor joint penetration; less than specified.

- Incomplete Fusion: Welds that are not fused completely to the base metal.

- Indentation: The depression on the surface of the base metal made during a seam, spot, or projection welding process.

- Induction Heating: A process of heating the metal through the metal’s resistance of eddy currents induced by electromagnetic induction. Usually used to preheat pipes and other structural steel before welding.

- Inert Gas: Inert gasses do not chemically react or alter the base metal. These are noble gasses like argon and helium, and they are used as shielding gasses to protect the weld pool.

- Infrared Radiation: Electromagnetic energy with wavelengths between 770 and 12000 nanometers.

- Intermittent Weld: A weld with a broken continuity by unwelded spaces between the welded spaces.

- Inverter Welding Power Source: A modern inverter technology that uses digitally controlled IGBT gates. It drastically improves efficiency and requires a far smaller transformer core inside the power source. As a result, the inverter welders are much lighter than the old transformer welders.

- Interpass Temperature: Specified maximum or minimum surface temperature of the previously laid weld in a multi-pass weld configuration.

Welding terminology on – J

- Joint: Structure line which separates the two base metal parts where they are welded together.

- Joint Design: The joint geometry with the dimensions of the welding joint.

- Joint Geometry: The dimensions and shape of the welding joint before welding it.

- Joint Penetration: Joint penetration represents a depth of a grove or flange weld that extends from its face into a joint and excludes reinforcement. It may include root penetration.

Welding terminology on – K

- Kerf: The cut width made with a metal cutting process.

- Keyhole TIG: Keyhole TIG requires no edge preparation, uses far less shielding gas, and produces repeatable, x-ray passing welds with exceptional quality. This welding process is far more efficient than traditional TIG.

Welding terms on – L

- Layer: A stratum of welded metal that consists of one or multiple weld beads.

- Leg Of a Fillet Weld: Spacing between the joint’s root and the fillet weld toe.

- Lap Joint: A joint between two overlapping elements. You can learn about a lap joint here.

- Local Stress Relieving: A post welding heat treatment process meant to relieve localized internal stresses.

- Local Preheating: Preheating a specific part of the structure.

- Liquidus: The lowest temperature at which a metal becomes completely liquid.

Welding terms on – M

- Macro Testing: A destructive testing method that examines the sections of a weld under a microscope after they were polished and etched.

- Manual Welding: Welding metal by hand.

- Machine Welding: Automated welding in which the machine performing a welding process is under constant watch by a human operator.

- Martensite: Martensite is a mirconstituent in quenched steel. It has an acicular or needle-like pattern on the polish surface and has the maximum hardness of all structures resulting from the decomposition of austenite.

- Melting Point: Required temperature to liquefy the metal.

- Melting Range: The temperature window between solid and liquid forms of metal.

- Melting Rate: The mass or length of a consumable electrode melted in a unit of time.

- MIG Welding: See GMAW above. MIG is just another name for the GMAW, and it’s an acronym for “metal inert gas.”

- Multi-Pass Welds: When multiple welds are layered one over another when welding a joint.

Welding terms on – N

- Non-Destructive Testing (NDT): Non-destructive testing methods evaluate the quality of welds without destroying the welded parts or their joint.

- Nozzle: Nozzle is located at the tip of the welding torch and it serves to direct the shielding gas flow.

- Nonferrous: Nonferrous metals do not contain iron. Some prominent examples are aluminum, copper, bronze, lead, nickel, gold, and titanium.

- Nugget: Nugget is a weld achieved with a spot resistance welding process.

Welding terms on – O

- Open Circuit Voltage (OCV): OCV or otherwise referred to as no-load voltage, is the electrical potential that exists between two terminals on the welding machine (positive and negative) before the welding arc is formed and the electric circuit is completed. The OCV is necessary to start the arc; it’s what forces the arc to jump from the electrode to the workpiece.

- Overhead Welding: Sometimes also called out-of-position welding, overhead welding is notoriously challenging because the gravity is working against the operator. This is the position in which the operator welds from underneath the joint, and the welding face is horizontal.

- Overlap: The protrusion of weld beyond the weld’s toe, face, or root.

- Oxyacetylene Welding Process: A flame-based welding process that uses oxygen and acetylene as burning fuel to melt the metal and fuse it together with or without filler metal.

- Oxyacetylene Cutting: Same as the oxy-fuel welding process except that the operator atains the temperature high enough to slice the metal.

- Oxy-Hydrogen Welding: This flame welding process uses oxygen and hydrogen as combustion fuel.

- Oxy-Propane Welding: Oxygen and propane gas are used as fuel for welding.

Welding terms on – P

- Pass: A single weld pass is a successful welding progression along a joint with a weld metal deposit.

- Partial Joint Penetration: A welded joint that hasn’t penetrated the base metal completely.

- Peel Test: A destructive weld inspection method that mechanically separates a lap joint by peeling.

- Peening: A mechanical process of working the metal with impact blows. It’s most often performed using a peening hammer to relieve the stresses of a freshly made weld.

- Percussive Welding: A resistance welding process in which the application of high pressure and an electrical discharge occur simultaneously.

- Perlite: Perlite is a lamellar aggregate of ferrite and iron carbide. It is created during the transformation of austenite at the lower critical point.

- Pitch: Welds spacing measured from center to center.

- Plug Weld: Plug welds are laid in a hole(s) of an overlapping metal so that the weld laid in the hole of the upper member penetrates through the member beneath it.

- Porosity: A welding defect that occurs when gas bubbles are trapped underneath the weld or protrude to the surface of the weld leaving a bubbly texture.

- Poke Welding: A spot welding process that applies electricity only to one electrode while the other electrode is clamped down to the metal.

- Post-Weld Heat Treatment: A heat treatment performed after the welding is completed. It’s most often done to relieve internal stresses.

- Power Factor Correction (PFC): PFC is a technology some welding machines posses. It reduces the amount of power spent; therefore, it reduces your electricity bill. PFC also corrects the input voltage allowing you to use a more dirty power source.

- Preheat Temperature: A specified temperature that must be achieved before welding.

- Preheating: Preheating is performed before welding using oxy-fuel, induction heating, specialized ovens, or ceramic pads. You can learn everything about preheating the metal before welding in our in-depth guide.

- Pressure Welding: Any welding process which involves a pressure appliance to achieve a welded joint.

- Procedure: The detailed explanation of elements of a process necessary to produce a specific result.

- Protective Atmosphere: A gas enveloping the welded joint to protect it from atmospheric contamination. Usually, inert gasses are used as shielding gas. For example, argon and helium are common shielding gasses.

- Projection Welding: A resistance welding process joining two or more surfaces or the ends of one member and the surface of another with localized projection welds.

- Pulsation Welding: A spot, seam, or projection welding process in which the current is interrupted one or more times while the pressure remains consistent.

- Pulsed MIG (GMAW-P): A modified MIG spray transfer process that doesn’t produce spatter because the wire doesn’t come in contact with the weld puddle. It allows welding almost all metals in every welding position.

- Pulsed TIG Welding: Pulsed TIG is a function available on high-end TIG welders that lets you alternate between high amperage and low amperage output many times a second. It’s ideal for welding thin metal because it improves your control over the heat input. Learn more about Pulsed TIG in our full guide.

- Push Angle: The travel angle when the electrode points in the travel direction. It defines the gun/torch angle.

Welding terms on – Q

- Quality Control (QC): The process of confirming that the finished product meets the specified demands.

- Quenching: Quenching is used to harden the metal by suddenly cooling it in with oil, water, and sometimes even compressed air.

Welding terms on – R

- Rated Load: The voltage and amperage output of the welding machine is rated to put out for a certain period of time before hitting the duty cycle limits.

- Reinforced Weld: The excess weld metal builds up on the weld face.

- Residual Stress: Internal stress that remains as a result of welding due to thermal/mechanical treatment.

- Reaction Stress: Residual stress which couldn’t occur if the welded elements were separated from the rest of the structure.

- Resistance Spot Welding (RSW): A resistance welding process that joins metal by applying pressure using copper electrodes and electrical current. To learn more about spot welding, please read our full guide.

- Resistance Welding: A group of different welding processes that share one common attribute — they all fuse metal using heat obtained as a result of metal resistance to the flow of electrical current and the application of pressure.

- Root of Joint: The closest point where two metal elements approach each other to be welded.

- Root Opening: The distance between the two welded elements at the root of the joint.

- Root Penetration: The depth that a weld penetrates into the joint’s root is measured from the centerline of the root cross-section.

- Root Surface: The exposed surface of the opposite side of the weld.

- Root Reinforcement: Reinforcing a weld on the opposite side from which the welding was performed.

- Root Crack: A crack in the weld or HAZ at the root of the weld.

- Rockwell Hardness Test: Rockwell hardness test measures the metal hardness by using pressure to penetrate a hard metal ball into its surface. By measuring the indentation, the metal is classified on a hardness scale.

Welding terms on – S

- Scratch Start TIG: A TIG arc starting method that involves scratching the surface of the welded metal with the tungsten electrode and lightly lifting the electrode from the surface.

- This action initiates the arc that jumps between the electrode and the welded metal. It’s the least favorable arc starting method because the tungsten electrode can contaminate the weld.

- Scarf Joint: A form of a butt joint.

- Seam Welding: A welding process that creates a continuous weld between or upon overlapping metal parts. The coalescence may start on the saying surfaces or proceed from the surface of one member. Seam weld may consist of a single weld bead or a series of multi-passes overlapping spot welds.

- Seal Weld: Welds are designed specifically to protect against leakage.

- Semi-automatic Arc Welding: An arc welding process with equipment that automatically controls wire feeding but the welding itself is manually performed.

- Series Welding: A resistance welding process in which two or more welds are simultaneously made by a single welding transformer with the current passing through each weld.

- Shielded Welding: All arc welding processes require a shielding gas, flux, or decomposition of electrode covering to provide protection from the atmosphere.

- Shielding Gas: A protective gas like argon, helium, or CO2 that actively prevents weld pool contamination from the atmosphere.

- Shielded Metal Arc Welding (SMAW): An arc welding process that joins metals by heating them with an arc between a covered electrode and the welded piece. The electrode covering burns as the electrode melts. This produces a shielding gas and the protective slag layer on top of the weld. The SMAW is more commonly referred to as stick welding, and you can learn more about it in the linked article.

- Shielded Carbon Arc Welding (SCAW): A carbon arc welding process that joins metal by heating them with an electric arc between a carbon electrode and the work. Shielding is achieved by burning the solid material fed into the arc or from a banket of flux layered on the work.

- Shrinkage Void: A cavity-type discontinuity typically formed by shrinkage as the metal solidifies.

- Single-phase Circuit: An electrical circuit that produces one alternating cycle within a 360-degree time frame.

- Skull: The unmelted residue from liquified filler material.

- Slot Weld: Slot welds are laid in the elongated hole(s) of one member in a lap or T joint configuration so that the weld penetrates to the other member underneath it and forms a bond.

- Slag Inclusion: Nonmetallic solid material that becomes trapped in the weld bead or between the welded metal and the base metal.

- Slugging: Adding a separate piece(s) of material in a joint before or while welding that results in a welded joint not complying with design requirements.

- Solidus: The highest temperature at which the metal remains solid.

- Spacer Strip: A metal bar or strip that’s placed at the root of the joint to serve as a backing and to maintain root opening during the welding process. It’s also used to bridge a too large root gap.

- Spool: A filler material wound on a cylinder. Usually used for MIG and FCAW processes.

- Spool Gun: A spool gun are usually used to weld aluminum but can be used to quickly switch to a stainless steel wire for example. The spool gun has a wire feeder and a spool roll container bult-in on the body of the gun.

- Spatter: Metal particles expelled as a result of the welding process.

- Spot Welding: Spot welding process joins overlapping metal using electrical resistance and applies pressure using copper electrodes.

- Spray Transfer (Arc Welding): Spray transfer propellers molten filler metal axially across the arc in small droplets.

- Square-Groove Weld: A typical butt weld joint configuration. Neither of the welded metal edges is beveled.

- Stich Welding: A method of using intermittent welds to join two or more metal parts.

- Stranded Electrode: Composite filler metal electrodes made of stranded wires which may mechanically enclose materials to stabilize the arc, improve properties, or provide shielding.

- Stress Relief Cracking: Intergranular cracking occurs in the HAZ of weld metal because of weldments exposure to elevated temperatures during post-weld heat treatment or high-temperature service.

- Stress Relief Heat Treatment: Uniform heating of a whole welded element or a portion of it to relieve internal stresses caused by welding.

- Stringer Bead: A type of weld bead made without appreciable weaving motion.

- Stud Welding: A process of bonding a fastener, nut, or bolt to a metal base. Fasteners may be threaded or not.

- Submerged Arc Welding (SAW): This welding process joins metal using an arc between a bare metal electrode and the work. To shield the weld pool, this welding process uses a blanket of granular, fusible material on the work. The filler metal is provided by the electrode and sometimes from the supplementary rod. Learn more about submerged arc welding here.

- Surfacing Weld: Welds are deposited using stringer or weave beads on an unbroken surface to produce certain properties or dimensions.

- Substrate: A base material that undergoes a plating process or receives surfacing welds.

- Surface Preparation: Operations are necessary to obtain the desired surface characteristics before welding, painting, machining, or another kind of part treatment.

- Synergic: In welding terminology, the word “synergic” means automatic synchronization of crucial welding parameters based on manual adjustments of one parameter. For example, if you modify wire feeding speed manually on a MIG welder, the voltage updates accordingly.

- Soldering: Soldering comprises multiple welding processes that join materials by heating them to a necessary temperature and by using a filler metal whose liquidus temperature doesn’t exceed 450 ºC (842 ºF) and remains below the solidus of the base materials.

Welding terms on – T

- T-joint: A joint configuration where two welded members are at a 90-degree angle to each other in the form of a letter “T.”

- Tack Welds: Welds are made to hold the separate pieces together in place until the final weld is made. They are usually made without filler metal unless using a gas metal arc welding process or stick welding.

- Tension Test: A destructive testing method (DT) is performed on a welded sample by pulling it apart until failure. To learn more about weld quality testing, read our full guide.

- Temper Colors: Steel experiences a specific discoloration when heated at low temperatures in an oxidizing atmosphere.

- Temporary Weld: A weld is produced to hold pieces together for temporary use like shipping, handling, or working on the workpiece.

- Thermocouple: A thermoelectric device used to measure the temperature of the metal. It’s necessary when preheating temperatures and interpass temperatures are specified in the welding procedure specification sheet.

- Thermal Stresses: Residual stresses occurring from uneven temperature distribution.

- Three-phase Circuit: An electrical circuit that delivers three cycles within a 360-degree time frame, and its cycles are 120 electrical degrees apart.

- TIG Welding (GTAW): Also called the GTAW welding process, TIG is an arc welding process that uses a non-consumable tungsten electrode and inert shielding gasses like argon and helium. Please refer to our full guide on TIG welding here.

- Tempering: Reheating the hardened steel below its critical temperature and then cooling it down. By tempering hardened steel, it’s possible to restore some of its ductility, developed toughness, and release some internal stresses.

- Thermite Welding: Thermite welding produces metal fusion using superheated liquid metal and slag. The heat source is a chemical reaction between metal oxide (usually iron oxide) and aluminum. Typically used in railroad welding.

- Thermite Crucible: The vessel in which thermite reaction occurs. It’s usually a single use prefabricated metal bucket.

- Thermite Mixture: A mixture in the crucible of finely ground metal oxide and aluminum. It also contains filler metal as alloying metals if it’s necessary to make a stronger bond.

- Thermite Mold: Usually formed on the spot, thermite mold shapes around the two metals to be thermite welded.

- Thermite Reaction: A chemical reaction between the metal oxide and aluminum that results in extreme heat that melts and welds metal in a matter of seconds. The thermite reaction is dangerous and requires multiple safety protocols.

- Torch: Usually used to name a TIG torch, a hand-held device that contains the tungsten electrode and provides a shielding gas coverage. But, some people also use the term “torch” to name a MIG gun, even if the word “gun” is more appropriate for the MIG “torch.”

- Torch Standoff Distance: A distance between a nozzle and a workpiece.

- Touch Start: More often referred to as lift arc start, the touch start is a TIG arc initiation method that establishes an arc between the tungsten electrode and the work piece by touching the surface of the metal with the tungsten and quickly lifting it upwards.

- Toe of Weld: The junction between weld’s face and metal’s base.

- Toe Crack: A weld crack that occurs at the toe. This is an unacceptable weld defect and the weld must be reworked.

- Travel Angle: The travel angle degree in push or pull configuration affects how much arc force is directed into the base metal. The travel angle varies depending on the welding process.

- Tungsten Electrode: A Tungsten electrode is a non-consumable electrode used in TIG welding and plasma arc welding processes. It is made of tungsten metal which is a rare metallic element with an extremely high melting point (3410 ºC). But various metal oxides are added in small quantities to the electrode composition to improve certain welding aspects. You can learn more about selecting tungsten electrodes in our guide.

Welding terms on – U

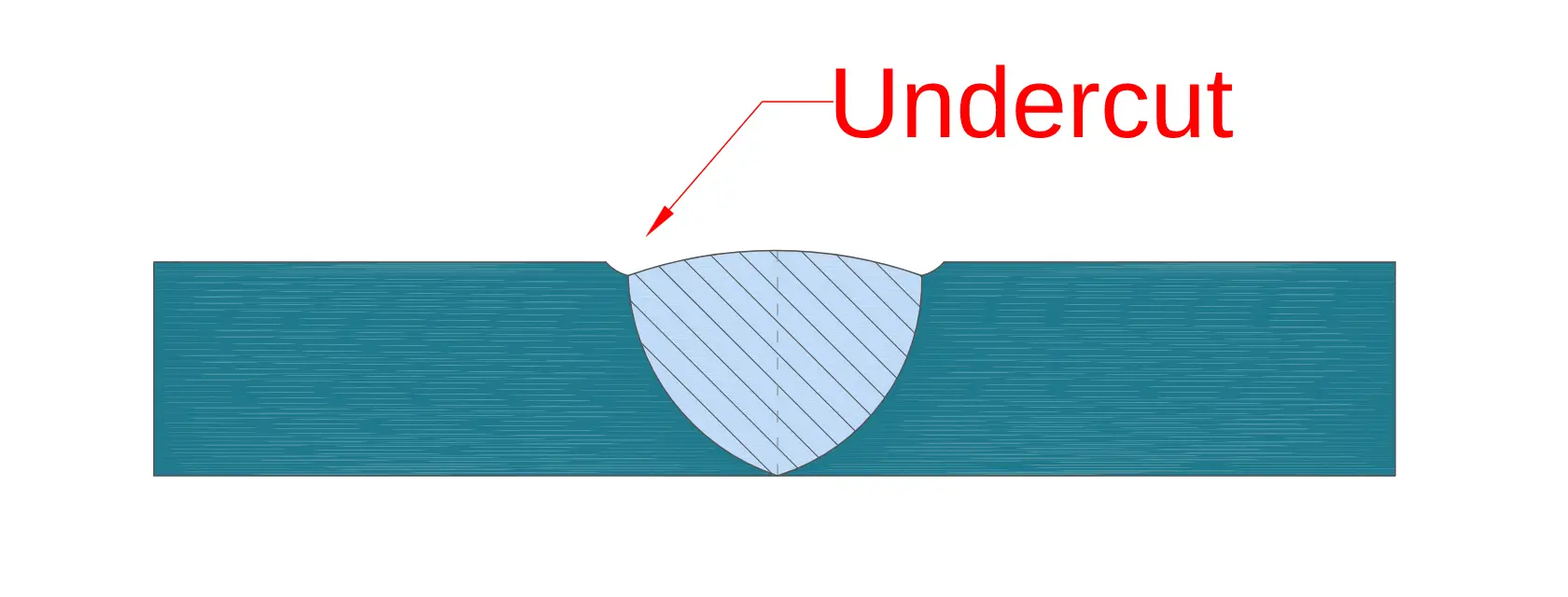

- Undercut: The undercut is a weld discontinuity where a groove weld is less filled near the toe of the weld.

This results in the reduced weld metal thickness near the toe of the weld compared to the thickness of the base metal overall.

- Underbead Crack: A crack located in the HAZ that doesn’t extend to the surface of the base metal.

- Upset: A localized volume increase of the weld reagion resulting from the application of pressure.

- Upset Welding: A resistance welding process that achieves fusion simultaneously over the entire area of bordering surfaces or along the joint using heat obtained from resistance to the electric current flow. Pressure is applied before heating and it’s maintained during the welding process.

- Up-slope Time: The time during which the welding current continuously increases from the starting welding current.

Welding terms on – V

- Vertical Position: Welding position in which the axis of the weld is approximately vertical.

- Voltage: The difference in charge potential between two points that acts as a force pushing electrons through a conductor.

- Voltage Regulator: Used to automatically maintain a constant voltage supply to the welding transformer.

- Volt-Amp Curve: A graph that shows the output characteristics of a power source used for welding.

Welding terms on – W

- Wandering Block Sequence: This is a block welding sequence that places successive weld blocks to joint metal in random order after several starting blocks are completed.

- Wandering Sequence: Randomly placed weld beads in a longitudinal sequence.

- Weld: A localized coalescence of metals or nonmetals created with or without the appliance of pressure, using heat to melt materials, and with or without the use of welding filler metal.

- Weld Crack: A crack present in the weld metal.

- Weld Metal: A portion of a weld which has been melted during the welding process including the filler metal.

- Weld Metal Area: The area of the weld’s cross-section area.

- Weld Transfer: Metal transfer method from the filler metal wire to the molten weld metal puddle.

- Welder: Usually referred to the welding operator — the person who performs a manual or semi-automated welding process. But, sometimes people use the term “welder” for the welding machine.

- Welder Performance Qualification: The demonstration qualification of the welder’s ability to create welds meeting certified standards.

- Welder Registration: Registering a welder certification or its photostatic copy.

- Welder Certification: Certifies welder in writing that they are able to create welds meeting the necessary standards.

- Weldability: The material’s capacity to be welded in fabrication conditions and to be used in suitable structure design and perform as expected in the intended service.

- Welding: A process that joins two or more materials with welds.

- Welding Current: The current in the welding circuit (electrode – metal – work clamp) while making the weld.

- Welding Cycle: The complete series of necessary events to complete the weld.

- Welding Generator: Generators rated for welding use to supply the necessary current that can power welding machines.

- Welding Leads: The cables that connect the work clamp and the electrode to the welding machine.

- Welding Machine: The welding machine is a power source for welding but it also includes a control panel with numerous settings necessary to perform a welding process.

- Welding Operator: A person operating manual or automated welding equipment.

- Welding Procedure: Detailed methods necessary to produce a weldment are provided in a welding procedure sheet.

- Welding Process: The welding process is a vague term used to define a set of methods and steps using certain technology to join metal. For example, TIG and MIG are both welding processes but they have many differences in terms of the underlying technology and necessary steps to perform to get a solid welding joint.

- Welding Rectifier: A device in the welding machine used to transform alternating current into a direct current.

- Welding Rod: Welding rod is a term used for multiple different filler metal rods. Sometimes stick electrodes are referred to as “welding rods,” but the actual meaning of the word is applied for filler metal that does not conduct the electrical current.

- Welding Sequence: Welds order in the weldment.

- Welding Positions: A position in which the operator welds the metal. There are four welding positions: flat, horizontal, vertical, and overhead.

- Welding Symbols: Welding symbols are used to annotate mechanical blueprints so that the welding operator knows precisely what kind of weld to make. Welding symbols contain crucial information like weld dimensions, position, the face of the joint, finishing method, and other vital data. You can learn everything about welding symbols in our in-depth guide and download our free PDF book on welding symbols.

- Wetting: Bonding or spreading of the liquid filler material or flux on a solid base metal.

- Wire Feed Speed: The rate at which the filler metal wire is fed into the molten weld pool when arc welding. Typically designated in inches per minute (“IPM”).

- Work Lead: The cable between the work clamp attached to the work piece and the welding power source.

Welding terms on – X

- X-Ray Testing: A non-destructive weld testing method that uses radiography (x-rays) to detect internal weld defects.

Welding terms on – Y

- Yield Strength: The amount of force needed to deform the material permanently.

- Yield Point: The point after which the yield strength has been breached. The material exhibits plastic deformation and will no longer return to its original shape from this point onwards.

- Young’s Modulus: Young’s modulus is the material’s mechanical property that measures the compressive or tensile stiffness of solid material when the force is applied axially.